-

產品搜尋

首頁 > Power/Data-Cable(進口電線電纜)> HELUKABEL-Wire and Cable > HELUKABEL-Shipwiring & Marine Cables 船舶電纜

30184570

商品編號: HELUKABEL-SHIPFLEX-113

SHIPFLEX 113 Cable for drag chain, single core, halogen-free, EMC-prefered type , meter marking 屏蔽隔離拖鏈船舶電纜,無鹵玉山 / 台新 / 華南 / 萬泰 / 兆豐 / 遠東 / 新光 / 永豐 / 第一 / 彰化 / 合庫 / 日盛 / 匯豐 / 渣打國泰世華 / 台北富邦 / 大眾銀行 / 台灣中小企銀/台中商銀 / 澳盛銀行

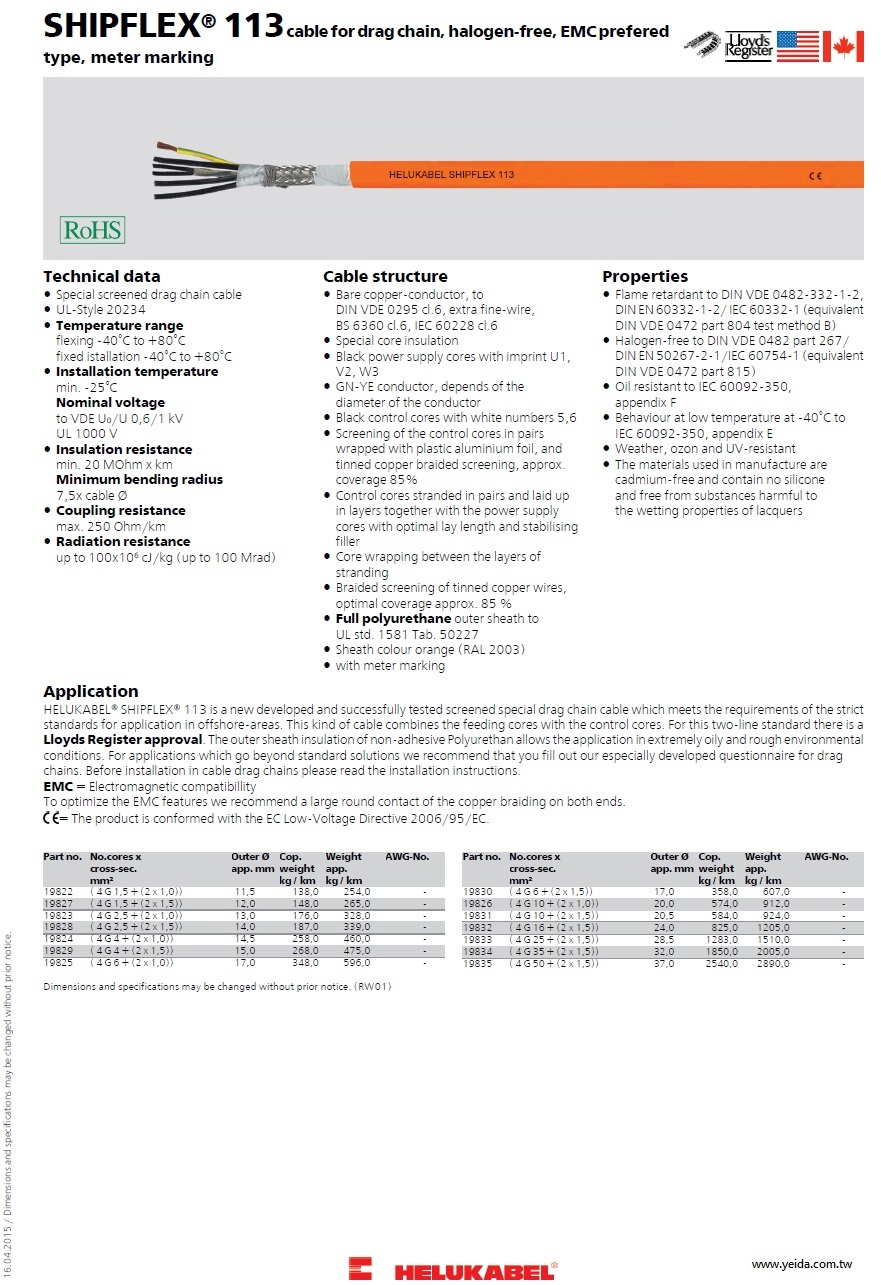

★★★★商品說明★★★★ SHIPFLEX® 113

cable for drag chain, halogen-free, EMC-preferred type, meter-marking

- Technical data

- Special screened drag chain cable

- UL-Style 20234

- Temperature range

flexing -40°C to +80°C

fixed istallation -40°C to +80°C - Installation temperature

min. -25°C

Nominal voltage

to VDE U0/U 0,6/1 kV

UL 1000 V - Insulation resistance

min. 20 MOhm x km

Minimum bending radius

7,5x cable Ø - Coupling resistance

max. 250 Ohm/km - Radiation resistance

up to 100x106 cJ/kg (up to 100 Mrad)

- Cable structure

- Bare copper-conductor, to

DIN VDE 0295 cl.6, extra fine-wire,

BS 6360 cl.6, IEC 60228 cl.6 - Special core insulation

- Black power supply cores with imprint U1,

V2, W3 - GN-YE conductor, depends of the

diameter of the conductor - Black control cores with white numbers 5,6

- Screening of the control cores in pairs

wrapped with plastic aluminium foil, and

tinned copper braided screening, approx.

coverage 85% - Control cores stranded in pairs and laid up

in layers together with the power supply

cores with optimal lay length and stabilising

filler - Core wrapping between the layers of

stranding - Braided screening of tinned copper wires,

optimal coverage approx. 85 % - Full polyurethane outer sheath to

UL std. 1581 Tab. 50227 - Sheath colour orange (RAL 2003)

- with meter marking

- Bare copper-conductor, to

- Properties

- Flame retardant to DIN VDE 0482-332-1-2,

DIN EN 60332-1-2/ IEC 60332-1 (equivalent

DIN VDE 0472 part 804 test method B) - Halogen-free to DIN VDE 0482 part 267/

DIN EN 50267-2-1/IEC 60754-1 (equivalent

DIN VDE 0472 part 815) - Oil resistant to IEC 60092-350,

appendix F - Behaviour at low temperature at -40°C to

IEC 60092-350, appendix E - Weather, ozon and UV-resistant

- The materials used in manufacture are

cadmium-free and contain no silicone

and free from substances harmful to

the wetting properties of lacquers

- Flame retardant to DIN VDE 0482-332-1-2,

- Application

HELUKABEL® SHIPFLEX® 113 is a new developed and successfully tested screened special drag chain cable which meets the requirements of the strict standards for application in offshore-areas. This kind of cable combines the feeding cores with the control cores. For this two-line standard there is a Lloyds Register approval. The outer sheath insulation of non-adhesive Polyurethan allows the application in extremely oily and rough environmental conditions. For applications which go beyond standard solutions we recommend that you fill out our especially developed questionnaire for drag chains. Before installation in cable drag chains please read the installation instructions.

Part no.

No.cores x

cross-sec.

mm²Outer Ø

approx. mm

Cop.

weightkg / km

Weight

approx. kg / km

AWG-No.

(4 G 1,5 + (2 x 1,0)) 11,5

138,0

254,0

-

(4 G 1,5 + (2 x 1,5)) 12,0

148,0

265,0

- (4 G 2,5 + (2 x 1,0)) 13,0

176,0

328,0

- (4 G 2,5 + (2 x 1,5)) 14,0

187,0

339,0

- (4 G 4 + (2 x 1,0)) 14,5

258,0

460,0

- (4 G 4 + (2 x 1,5)) 15,0

268,0

475,0

- (4 G 6 + (2 x 1,0)) 17,0

348,0

596,0

- (4 G 6 + (2 x 1,5)) 17,0

358,0

607,0

- (4 G 10 + (2 x 1,0)) 20,0

574,0

912,0

- (4 G 10 + (2 x 1,5)) 20,5

584,0

924,0

- (4 G 16 + (2 x 1,5)) 24,0

825,0

1205,0

- (4 G 25 + (2 x 1,5)) 28,5

1283,0

1510,0

- (4 G 35 + (2 x 1,5)) 32,0

1850,0

2005,0

- (4 G 50 + (2 x 1,5)) 37,0

2540,0

2890,0

-

2024/5/9 下午 02:23:13

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司