商品編號: HELUKABEL-NTSCGEWOU

玉山 / 台新 / 華南 / 萬泰 / 兆豐 / 遠東 / 新光 / 永豐 / 第一 / 彰化 / 合庫 / 日盛 / 匯豐 / 渣打國泰世華 / 台北富邦 / 大眾銀行 / 台灣中小企銀/台中商銀 / 澳盛銀行

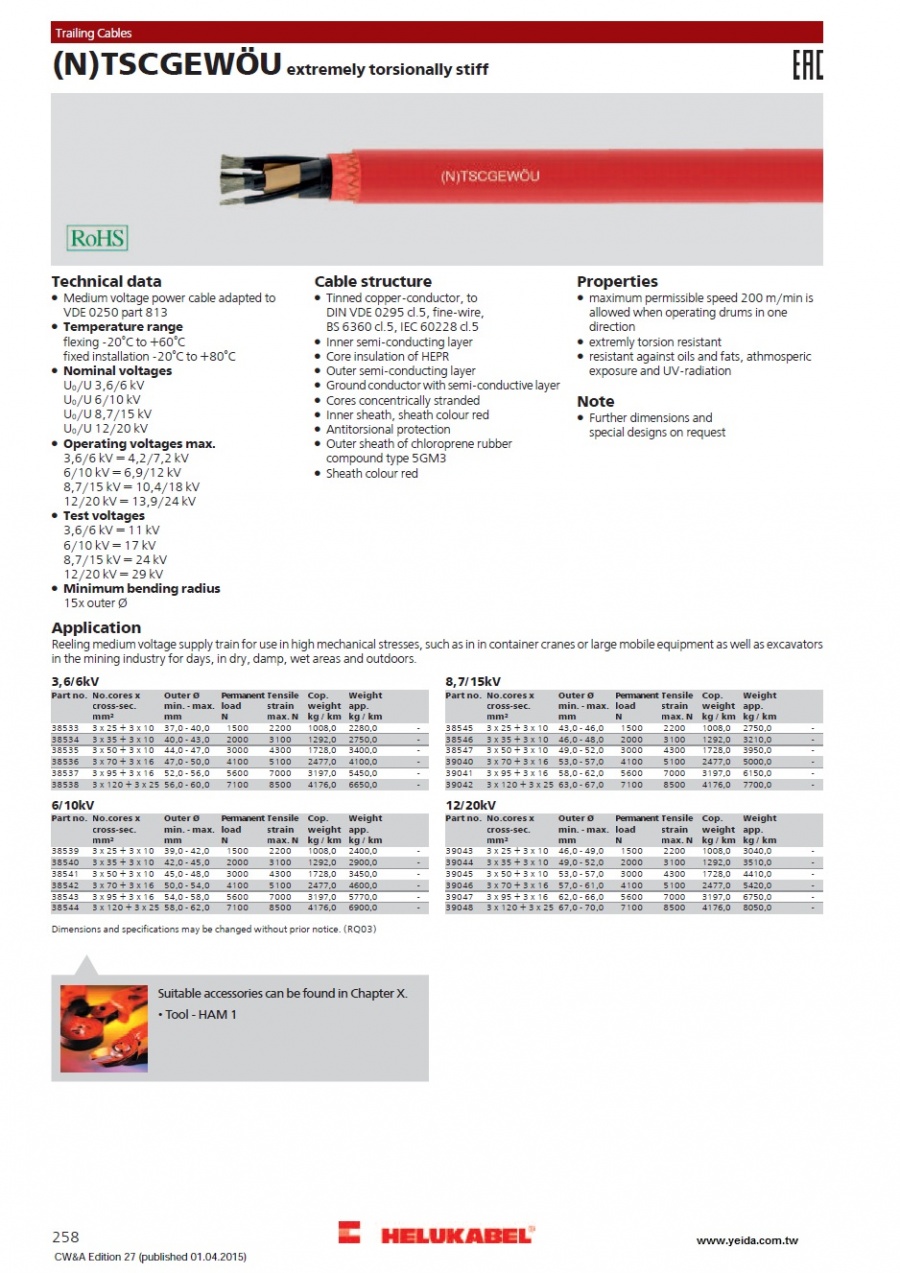

Technical data Medium voltage power cable adapted to Temperature range Nominal voltages 0 /U 3,6/6 kV 0 /U 6/10 kV 0 /U 8,7/15 kV 0 /U 12/20 kVOperating voltages max. Test voltages Minimum bending radius Cable structure Tinned copper-conductor, to Inner semi-conducting layer Core insulation of HEPR Outer semi-conducting layer Ground conductor with semi-conductive layer Cores concentrically stranded Inner sheath, sheath colour red Antitorsional protection Outer sheath of chloroprene rubber Sheath colour red Properties maximum permissible speed 200 m/min is extremly torsion resistant resistant against oils and fats, athmosperic Note Further dimensions and Application Reeling medium voltage supply train for use in high mechanical stresses, such as in in container cranes or large mobile equipment as well as excavators in the mining industry for days, in dry, damp, wet areas and outdoors. 捲軸中壓供電列車在高機械應力,使用例如在集裝箱起重機或大型移動設備,以及在採礦業挖掘機天,在乾燥,潮濕,潮濕地區和戶外。

3,6/6kV Part no.

No.cores x

Outer Ø

min. - max.

mm

Permanent

N

Tensile

max. N

Cop.

kg / km

Weight

app. kg / km

38533

3 x 25 + 3 x 10 37,0 - 40,0

1500

2200

1008,0

2280,0

-

38534

3 x 35 + 3 x 10 40,0 - 43,0

2000

3100

1292,0

2750,0

-

38535

3 x 50 + 3 x 10 44,0 - 47,0

3000

4300

1728,0

3400,0

-

38536

3 x 70 + 3 x 16 47,0 - 50,0

4100

5100

2477,0

4100,0

-

38537

3 x 95 + 3 x 16 52,0 - 56,0

5600

7000

3197,0

5450,0

-

38538

3 x 120 + 3 x 25 56,0 - 60,0

7100

8500

4176,0

6650,0

-

6/10kV Part no.

No.cores x

Outer Ø

min. - max.

mm

Permanent

N

Tensile

max. N

Cop.

kg / km

Weight

app. kg / km

38539

3 x 25 + 3 x 10 39,0 - 42,0

1500

2200

1008,0

2400,0

-

38540

3 x 35 + 3 x 10 42,0 - 45,0

2000

3100

1292,0

2900,0

-

38541

3 x 50 + 3 x 10 45,0 - 48,0

3000

4300

1728,0

3450,0

-

38542

3 x 70 + 3 x 16 50,0 - 54,0

4100

5100

2477,0

4600,0

-

38543

3 x 95 + 3 x 16 54,0 - 58,0

5600

7000

3197,0

5770,0

-

38544

3 x 120 + 3 x 25 58,0 - 62,0

7100

8500

4176,0

6900,0

-

8,7/15kV Part no.

No.cores x

Outer Ø

min. - max.

mm

Permanent

N

Tensile

max. N

Cop.

kg / km

Weight

app. kg / km

38545

3 x 25 + 3 x 10 43,0 - 46,0

1500

2200

1008,0

2750,0

-

38546

3 x 35 + 3 x 10 46,0 - 48,0

2000

3100

1292,0

3210,0

-

38547

3 x 50 + 3 x 10 49,0 - 52,0

3000

4300

1728,0

3950,0

-

39040

3 x 70 + 3 x 16 53,0 - 57,0

4100

5100

2477,0

5000,0

-

39041

3 x 95 + 3 x 16 58,0 - 62,0

5600

7000

3197,0

6150,0

-

39042

3 x 120 + 3 x 25 63,0 - 67,0

7100

8500

4176,0

7700,0

-

12/20kV Part no.

No.cores x

Outer Ø

min. - max.

mm

Permanent

N

Tensile

max. N

Cop.

kg / km

Weight

app. kg / km

39043

3 x 25 + 3 x 10 46,0 - 49,0

1500

2200

1008,0

3040,0

-

39044

3 x 35 + 3 x 10 49,0 - 52,0

2000

3100

1292,0

3510,0

-

39045

3 x 50 + 3 x 10 53,0 - 57,0

3000

4300

1728,0

4410,0

-

39046

3 x 70 + 3 x 16 57,0 - 61,0

4100

5100

2477,0

5420,0

-

39047

3 x 95 + 3 x 16 62,0 - 66,0

5600

7000

3197,0

6750,0

-

39048

3 x 120 + 3 x 25 67,0 - 70,0

7100

8500

4176,0

8050,0

-

30172533

2024/5/10 上午 12:50:19

2024/5/10 上午 12:50:19