商品編號: Seacoast-M85045

M85045 US Navy Shipboard Cable > MIL-PRF-85045 美國海事船舶軍規光纖電線

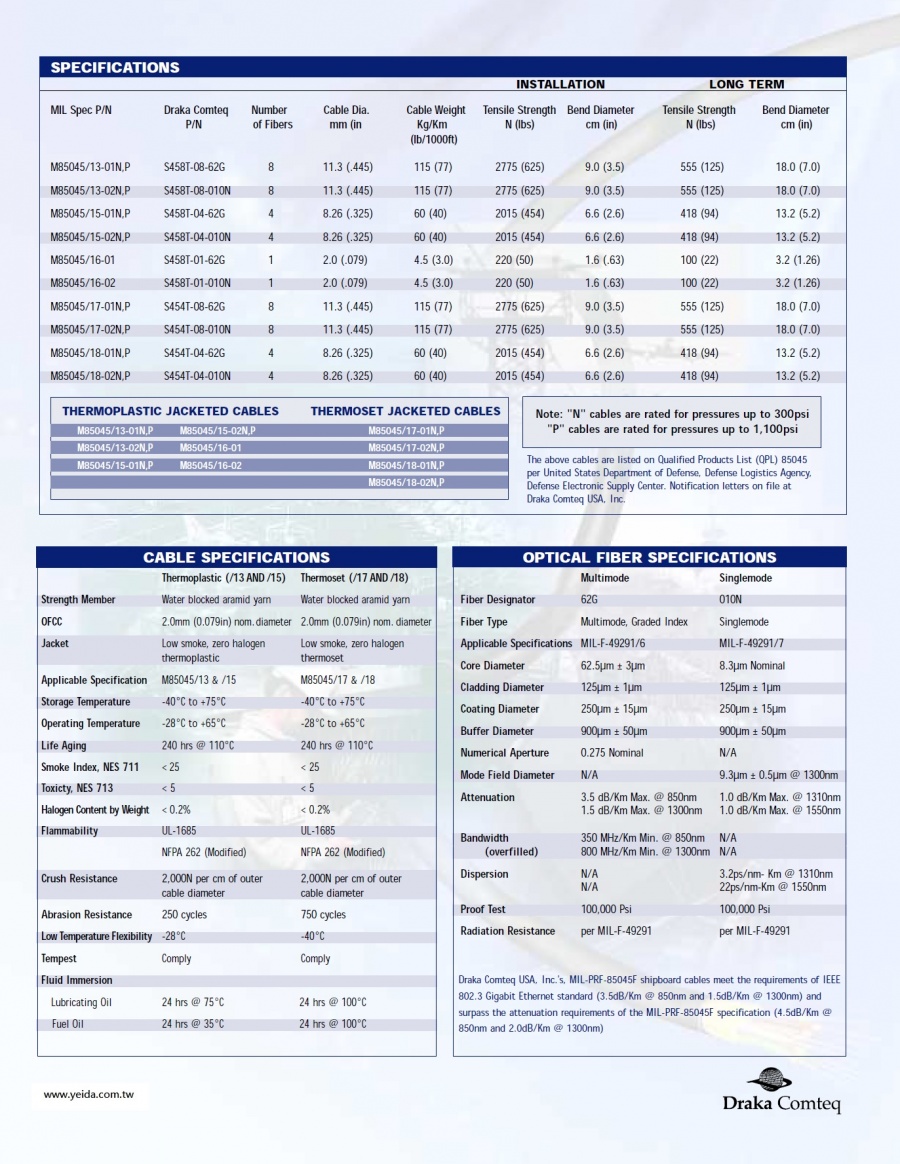

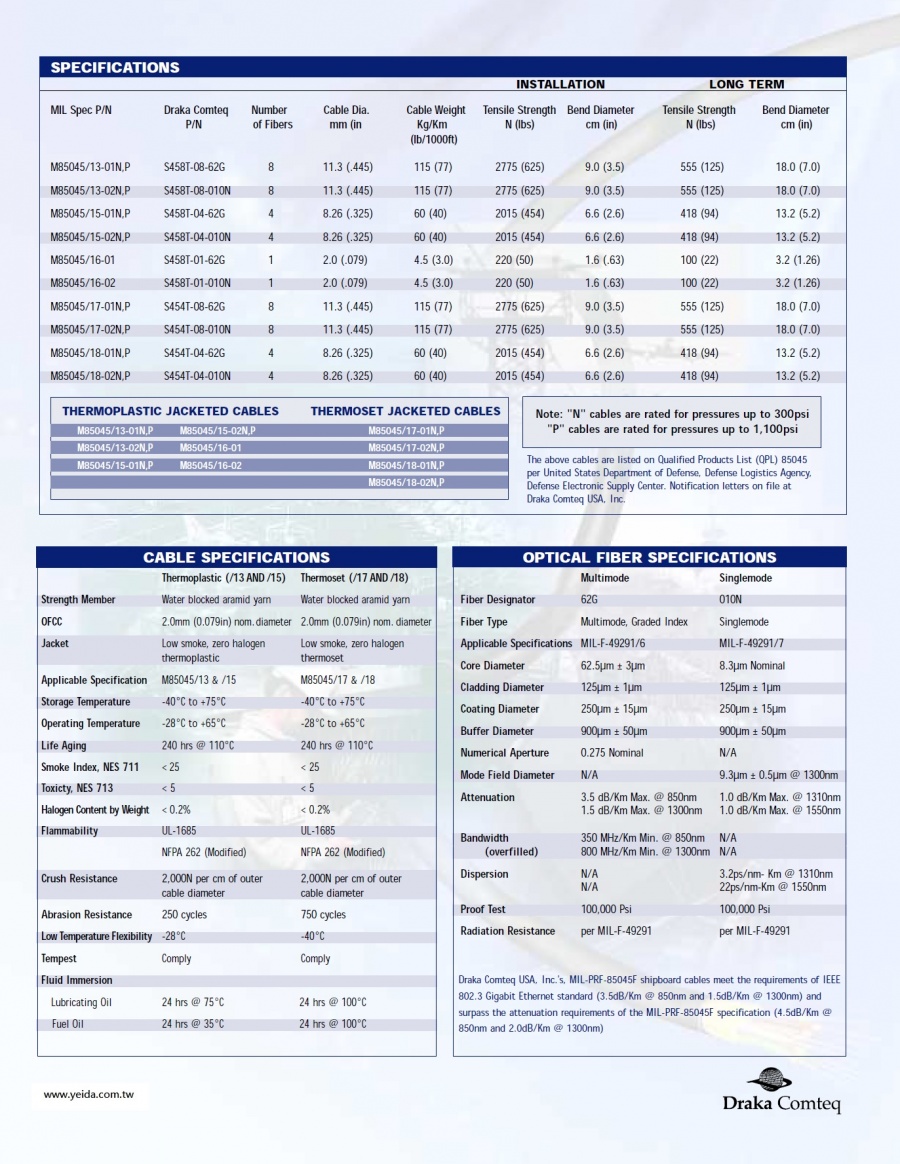

SHIPBOARD FIBER OPTIC CABLES (MIL-PRF-85045F Qualified)

raka Comteq USA, Inc.’s, qualified fiber optic shipboard

cables provide superior optical performance in a craftfriendly

and flexible cable design.

Draka Comteq USA, Inc.’s, shipboard

fiber optic cables are designed using

a tight buffered, water-blocked

construction with low smoke, zerohalogen

jacketing materials.

Adhering to the United States

Department of Defense MIL-PRF-

85045F specification document,

Draka Comteq USA, Inc., offers these

cables in one, four and eight fiber

configurations. The optical fiber

cable component (OFCC) consists of

an optical fiber with a 900μm diameter

tight buffer, reinforced with

aramid yarns, and encased in a

2.0mm flexible zero-halogen jacket.

In addition, Draka Comteq manufactures

optical fibers that are radiation resistant and qualified

per the applicable MIL-F-49291 specification document to

insure system survivability in the event of radiation exposure.

This family of cables has passed a stringent qualification program

to insure full compliance to the MIL-PRF-85045F document and

the applicable specification sheets. The program includes

tests such as acid gas generation, halogen content, smoke

generation and flame propagation, toxicity, fluid immersion,

thermal shock, humidity, electromagnetic resistance, low/high

pressure salt water blocking and many other

highly demanding requirements. In addition

to the qualification program, the U.S.

Department of Defense closely monitors the

manufacturing process, the final cable testing

and the periodic re-qualification tests

to insure the highest degree of product

quality.

These cables are available with either a

thermoplastic or a cross-linked, thermoset

LSZH outer jacket. The thermoplastic

jacketing system offers good resistance

to chemicals, fluids, fungus and abrasion;

offers low smoke, low toxic fumes and acid

gas generation. The cross-linked, thermoset

jacket is more rugged and offers improved

thermal aging and fluid resistance,improved

abrasion, scrape and cut through resistance and better flexibility

at cold temperature extremes. Draka Comteq USA, Inc.’s, unique

thermoset jacketing process provides an extremely rugged and

cost effective cable design while maintaining superior optical

performance and long term reliability.

| .jpg)

Seacoast-M85045

2024/4/29 上午 08:00:18

2024/4/29 上午 08:00:18