商品編號: Radix-DuraFlex550

Radix-DuraFlex® 550 HIGH-TEMPERATURE LEAD WIRE Mica glass composite (300V-UL 5390) (600V – UL 5400) (24 AWG – 8 AWG) 550°C 鍍鎳銅+雲母帶+玻璃絲矽膠編織 柔韌性佳高溫線

Characteristics

• Outperforms UL 5128/5107 MGT products:

~ U nique insulation system offers outstanding

heat-aged flexibility for longer service life.

~ P asses UL 2X mandrel test after heat aging

(UL 5128/5107 is 3X mandrel).

~ Modified silicone jacket virtually eliminates dermatitis

problems associated with handling fiberglass and braid fray.

~ 550°C temperature rating allows wire to be installed in

extreme environments and reduces the cost of added thermal

protection (glass sleeve, ceramic insulator, etc).

~ E xcellent cutting and stripping characteristics, making it ideal

for high volume manufacturing and assembly.

~ P rovides dimensional consistency and uniformity.

• Resists braid pushback.

• Withstands mechanical abuse.

DuraFlex® 550

550C/300V and 550C/600V HIGH-TEMPERATURE

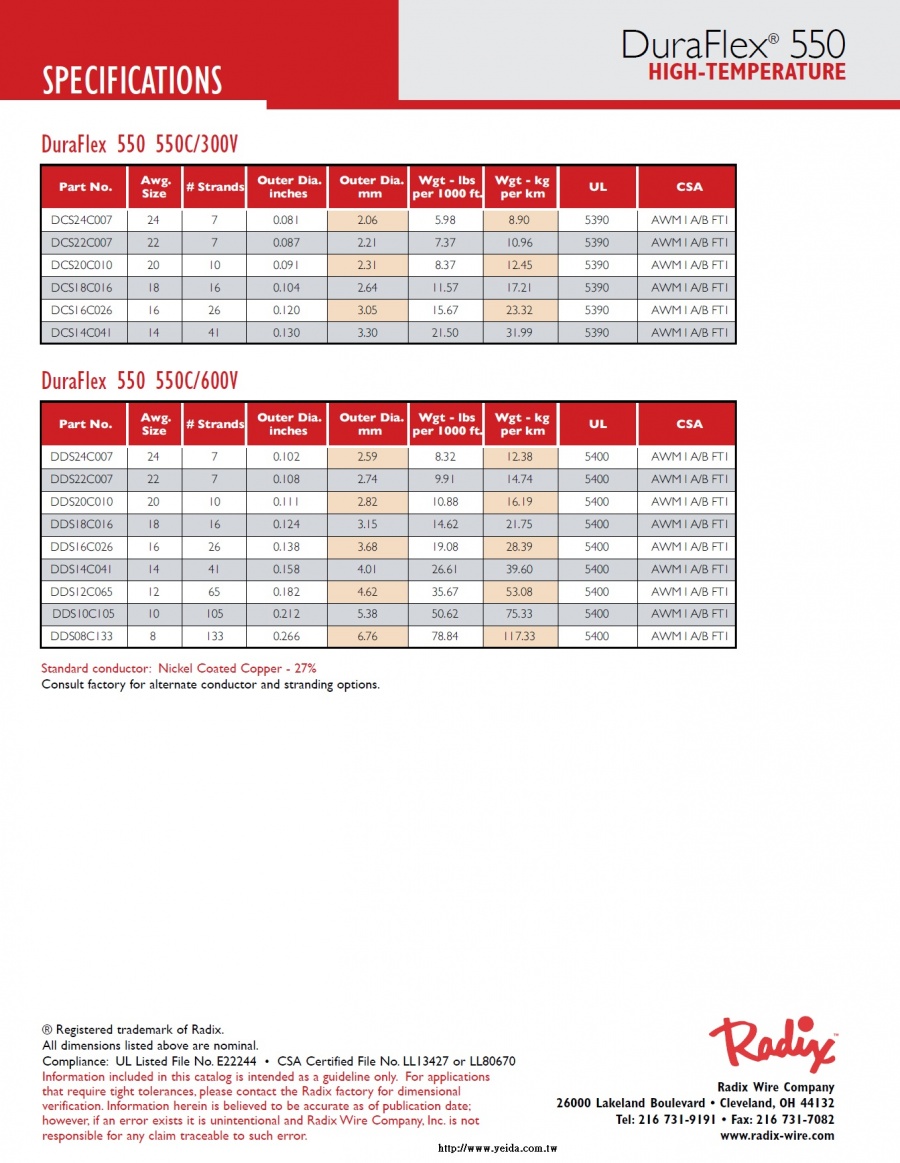

Ratings / Approvals

550°C – 300 Volts - UL 5390 / AWM I A/B FT1

550°C – 600 Volts - UL 5400 / AWM I A/B FT1

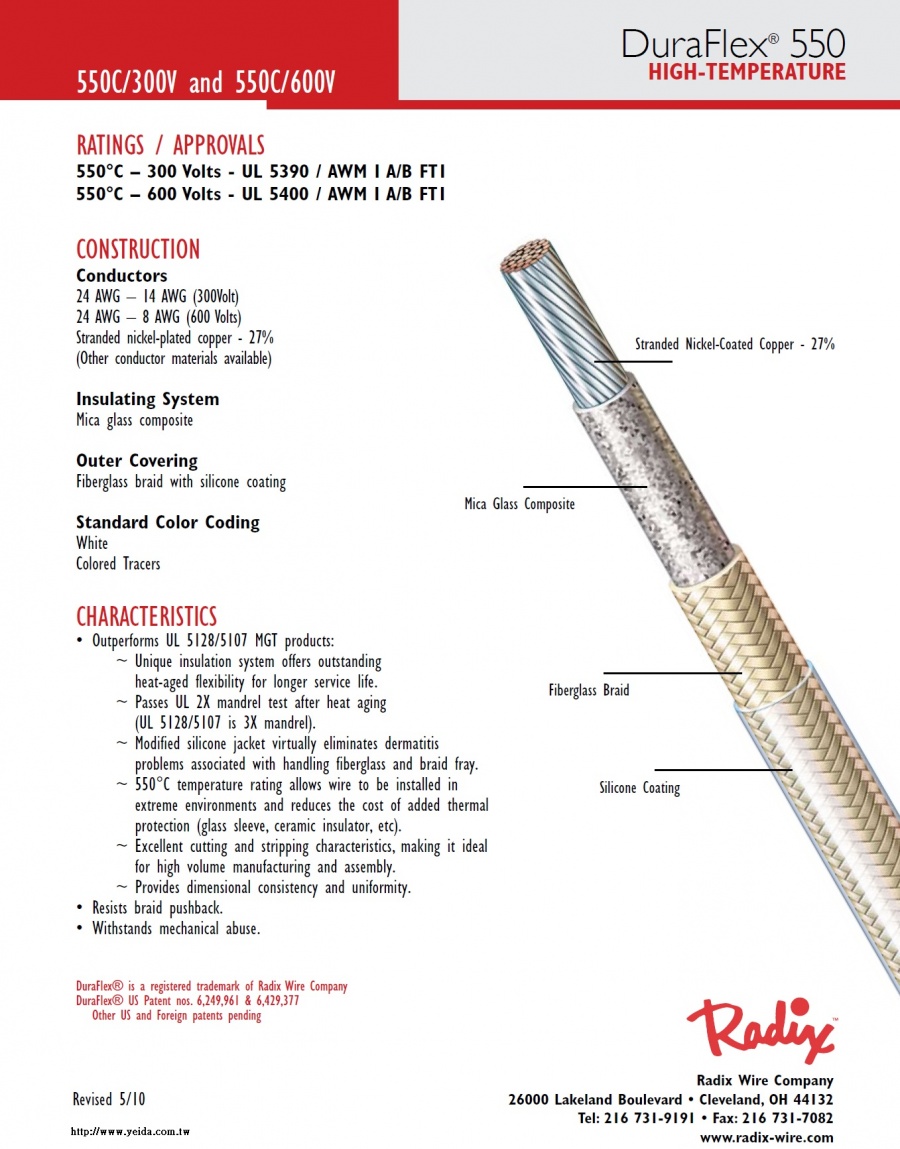

Construction

Conductors

24 AWG – 14 AWG (300Volt)

24 AWG – 8 AWG (600 Volts)

Stranded nickel-plated copper - 27%

(Other conductor materials available)

Insulating System

Mica glass composite

Outer Covering

Fiberglass braid with silicone coating

Standard Color Coding

White

Colored Tracers

Characteristics

• Outperforms UL 5128/5107 MGT products:

~ U nique insulation system offers outstanding

heat-aged flexibility for longer service life.

~ P asses UL 2X mandrel test after heat aging

(UL 5128/5107 is 3X mandrel).

~ Modified silicone jacket virtually eliminates dermatitis

problems associated with handling fiberglass and braid fray.

~ 550°C temperature rating allows wire to be installed in

extreme environments and reduces the cost of added thermal

protection (glass sleeve, ceramic insulator, etc).

~ E xcellent cutting and stripping characteristics, making it ideal

for high volume manufacturing and assembly.

~ P rovides dimensional consistency and uniformity.

• Resists braid pushback.

• Withstands mechanical abuse.

|

DuraFlex® 550

550C/300V and 550C/600V HIGH-TEMPERATURE

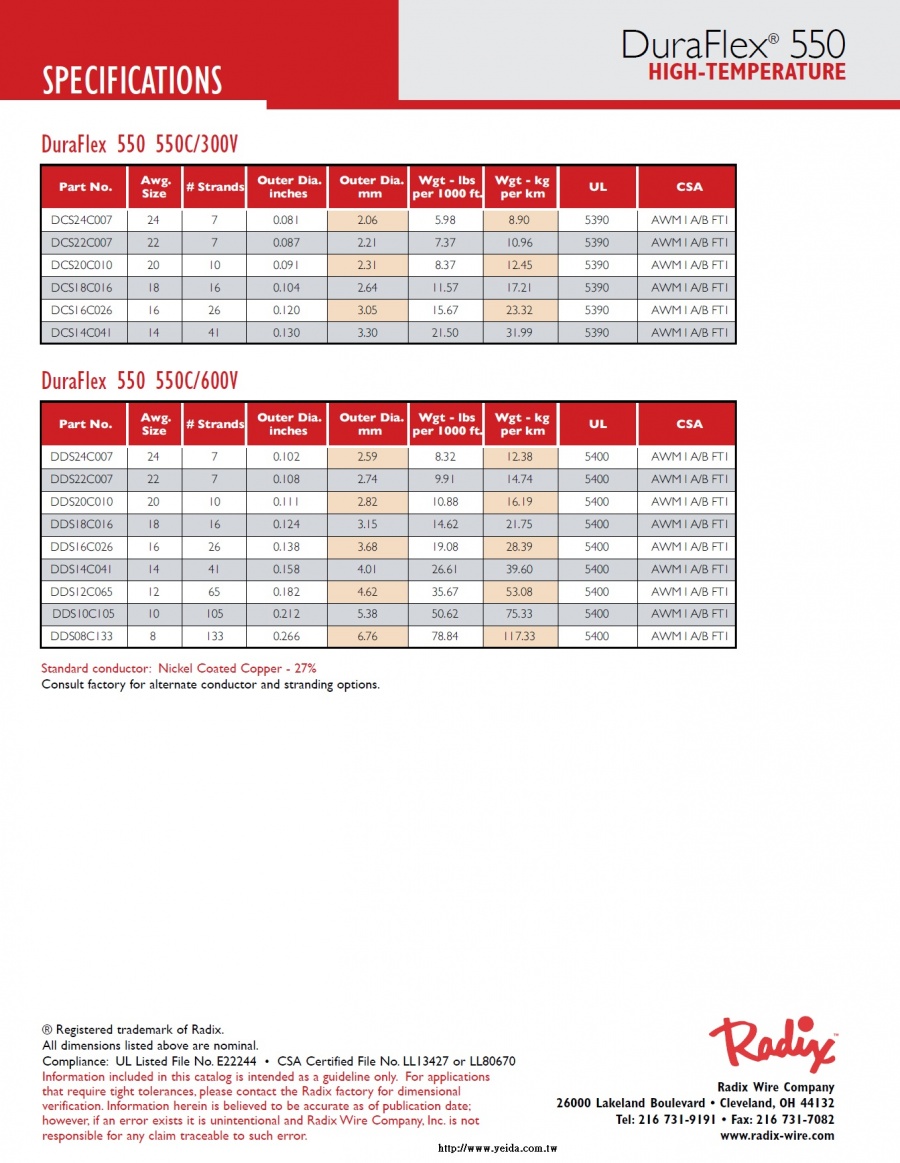

Ratings / Approvals

550°C – 300 Volts - UL 5390 / AWM I A/B FT1

550°C – 600 Volts - UL 5400 / AWM I A/B FT1

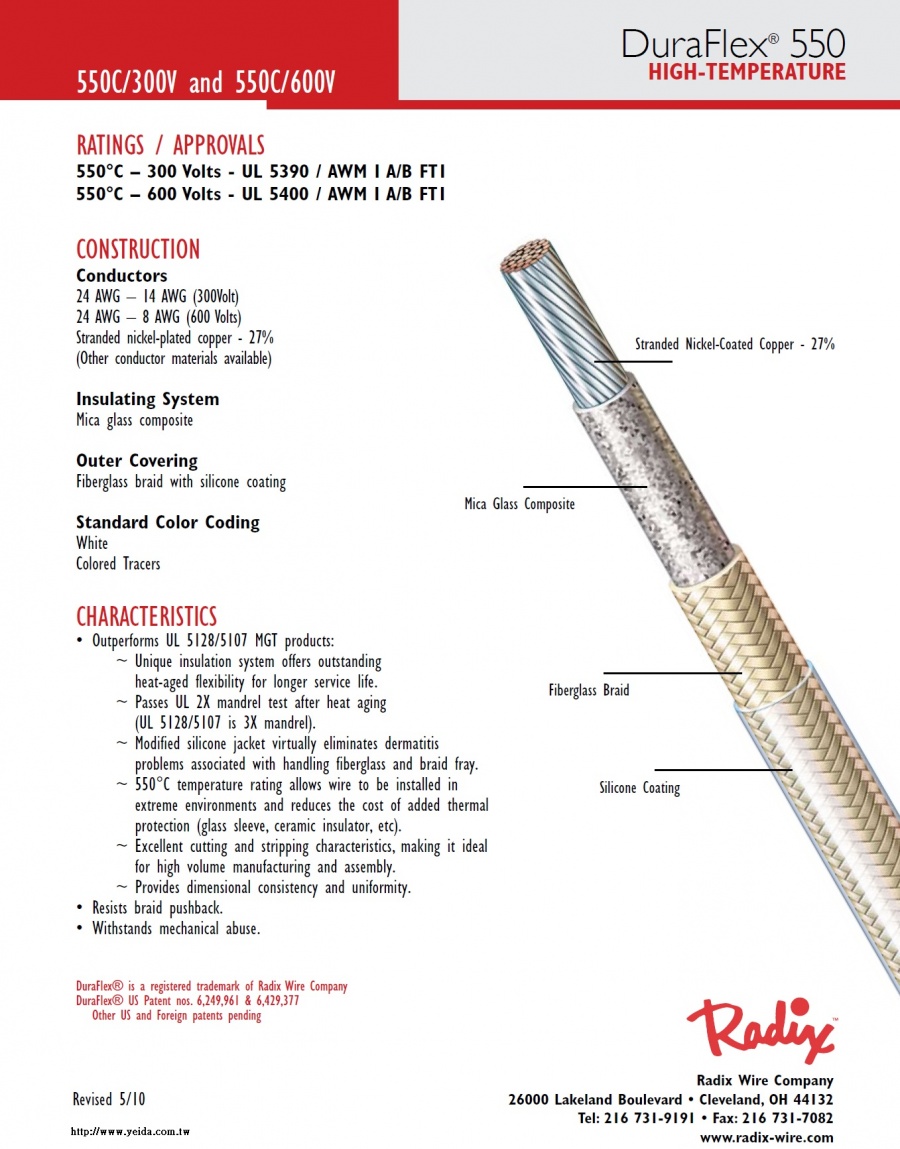

Construction

Conductors

24 AWG – 14 AWG (300Volt)

24 AWG – 8 AWG (600 Volts)

Stranded nickel-plated copper - 27%

(Other conductor materials available)

Insulating System

Mica glass composite

Outer Covering

Fiberglass braid with silicone coating

Standard Color Coding

White

Colored Tracers

Characteristics

• Outperforms UL 5128/5107 MGT products:

~ U nique insulation system offers outstanding

heat-aged flexibility for longer service life.

~ P asses UL 2X mandrel test after heat aging

(UL 5128/5107 is 3X mandrel).

~ Modified silicone jacket virtually eliminates dermatitis

problems associated with handling fiberglass and braid fray.

~ 550°C temperature rating allows wire to be installed in

extreme environments and reduces the cost of added thermal

protection (glass sleeve, ceramic insulator, etc).

~ E xcellent cutting and stripping characteristics, making it ideal

for high volume manufacturing and assembly.

~ P rovides dimensional consistency and uniformity.

• Resists braid pushback.

• Withstands mechanical abuse.

|

|

5527300

2024/5/8 上午 08:32:09

2024/5/8 上午 08:32:09