-

產品搜尋

首頁 > ALPHA- 電線電纜專區> ALPHA-Hook Up Wire 電子線 > ALPHA-MIL-W-16878 軍規電子線

ALPHA-5877

商品編號: ALPHA-5877

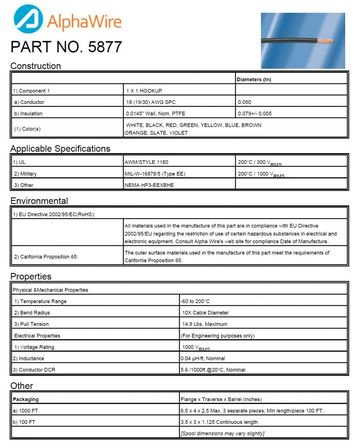

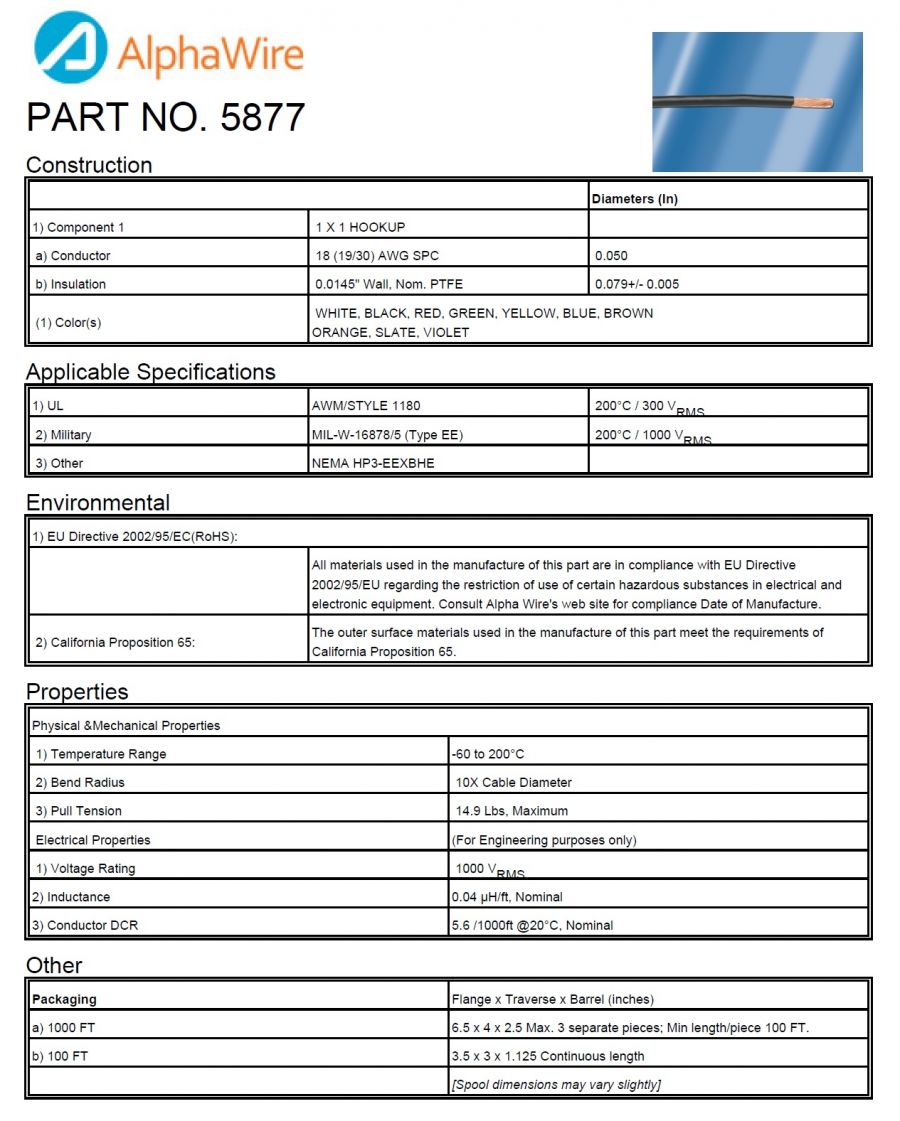

ALPHA-5877 Awg18 1,000V PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBEE, UL AWM 1180 軍規鐵氟龍電子線

Part # Voltage AWG Stranding Insulation Thickness Insulation Diameter Insulation Material Applicable Specifications 5877 1000 18 19/30 0.0145 0.079 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBHE, UL AWM 1180

Applicable SpecificationsPart # Voltage AWG Stranding Insulation Thickness Insulation Diameter Insulation Material 5874 1000 24 19/36 0.0145 0.054 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBEE, UL AWM 1180 5875 1000 22 19/34 0.014 0.06 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBFE, UL AWM 1180 5876 1000 20 19/32 0.014 0.068 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBGE, UL AWM 1180 5877 1000 18 19/30 0.0145 0.079 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBHE, UL AWM 1180 5878 1000 16 19/29 0.016 0.089 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBJE, UL AWM 1180 5879 1000 14 19/27 0.017 0.106 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBKE, UL AWM 1180 5879/10 1000 10 37/26 0.017 0.145 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBMG, UL AWM 1180 5879/12 1000 12 19/25 0.017 0.125 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBLE, UL AWM 1180 5879/8 1000 8 133/29 0.02 0.209 PTFE CA Prop 65, MIL-W-16878E-TYPE EE, NEMA HP3-EEXBNL 5951 0 30 Solid 0.0045 0.02 PVDF CA Prop 65, UL AWM 1423 5952 0 28 Solid 0.0055 0.024 PVDF CA Prop 65, UL AWM 1422 5953 0 26 Solid 0.0055 0.027 PVDF CA Prop 65, UL AWM 1422 5954 0 24 Solid 0.0045 0.03 PVDF CA Prop 65, UL AWM 1423 6112 600 6 266/30 0.06 0.32 Rubber 6113 600 4 392/30 0.06 0.375 Rubber 6115 600 2 644/30 0.06 0.44 Rubber 6116 600 1 784/30 0.08 0.515 Rubber 6117 600 1/0 1026/30 0.08 0.55 Rubber 6118 600 2/0 1254/30 0.08 0.59 Rubber 6119 600 3/0 1615/30 0.08 0.66 Rubber 2024/5/13 上午 05:36:34

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司