-

產品搜尋

首頁 > ALPHA- 電線電纜專區> ALPHA-Xtra-Guard® 2 高性能耐磨电缆 > ALPHA-Xtra-Guard® 2 Unshielded Multiconductor 防油 耐磨高性能多芯無隔離控制电缆

ALPHA-25010-25

商品編號: ALPHA-25010-25

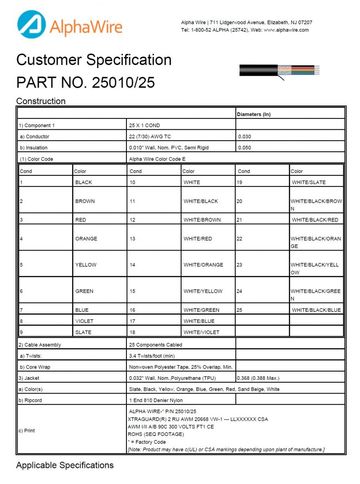

ALPHA-25010/25 UL 10002, UL 20668 Awg 22x25C 300V Xtra-Guard® 2 高性能电缆

Applicable SpecificationsPart # Type Shielding Voltage AWG # of Elements Jacket Diameter 25002 Conductor UNSHIELDED 300 22 2 0.168 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25003 Conductor UNSHIELDED 300 22 3 0.176 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25004 Conductor UNSHIELDED 300 22 4 0.189 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25006 Conductor UNSHIELDED 300 22 6 0.219 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25008 Conductor UNSHIELDED 300 22 8 0.235 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25010 Conductor UNSHIELDED 300 22 10 0.268 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25010/15 Conductor UNSHIELDED 300 22 15 0.299 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25010/20 Conductor UNSHIELDED 300 22 20 0.331 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25010/25 Conductor UNSHIELDED 300 22 25 0.368 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25012 Conductor UNSHIELDED 300 24 2 0.156 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25013 Conductor UNSHIELDED 300 24 3 0.163 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25014 Conductor UNSHIELDED 300 24 4 0.175 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25016 Conductor UNSHIELDED 300 24 6 0.201 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25018 Conductor UNSHIELDED 300 24 8 0.215 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25020 Conductor UNSHIELDED 300 24 10 0.244 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25020/15 Conductor UNSHIELDED 300 24 15 0.271 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25020/20 Conductor UNSHIELDED 300 24 20 0.3 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25020/25 Conductor UNSHIELDED 300 24 25 0.332 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 10002, UL AWM 20668, UL VW/1 25052 Conductor UNSHIELDED 300 20 2 0.208 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 1569, UL AWM 20668, UL VW/1 25053 Conductor UNSHIELDED 300 20 3 0.219 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT1, UL AWM 1569, UL AWM 20668, UL VW/1

2024/5/14 上午 10:11:58

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司