|

Low-Smoke, Non-Halogen Coaxial Cables

Military Shipboard Qualifications

Military Shipboard Qualifications

Since the 1940s, MIL-C-17 has been the definitive specification for coaxial, triaxial and other high performance

radio frequency cables. Beginning in 1970, United States standards making organizations have been establishing safety requirements

for product flame retardance, and more recently, smoke, toxicity and corrosive off-gassing properties. With revision "G", MIL-C-17

adapts qualification tests for each of these characteristics, which assures the coaxial cable you select for your applications will meet

the minimum safety standards.

In 1993, per MIL-STD-454, the military began the process of inactivating the use of polyvinylchloride (PVC) radio frequency

cables, that were used in military weapons systems. A new series of cross-linked, low-smoke, non-halogen coaxial cables were qualified

to replace the older inactivated PVC versions.

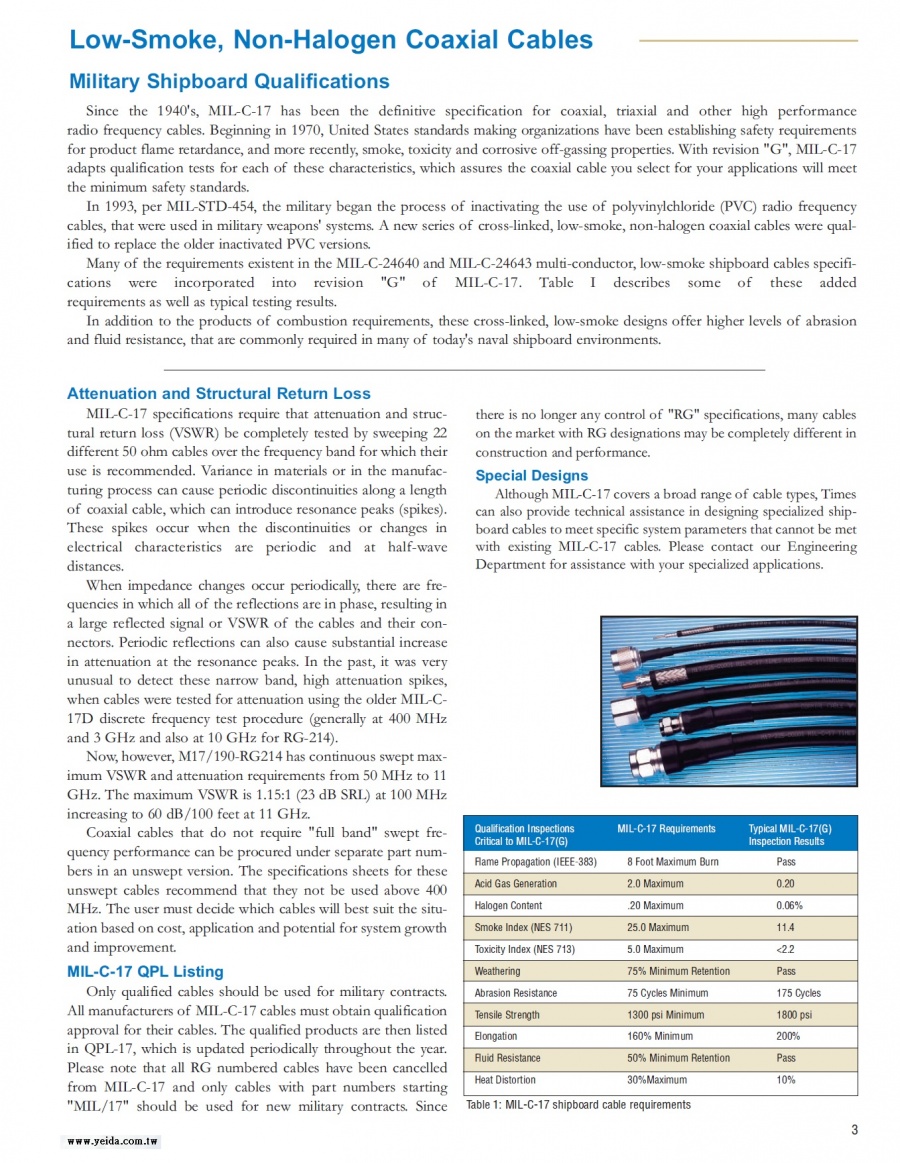

Many of the requirements existent in the MIL-C-24640 and MIL-C-24643 multi-conductor, low-smoke shipboard cables specifications

were incorporated into revision "G" of MIL-C-17. Table I describes some of these added

requirements as well as typical testing results.

In addition to the products of combustion requirements, these cross-linked, low-smoke designs offer higher levels of abrasion

and fluid resistance, that are commonly required in many of todays naval shipboard environments.

Low-Smoke, Non-Halogen Coaxial Cables

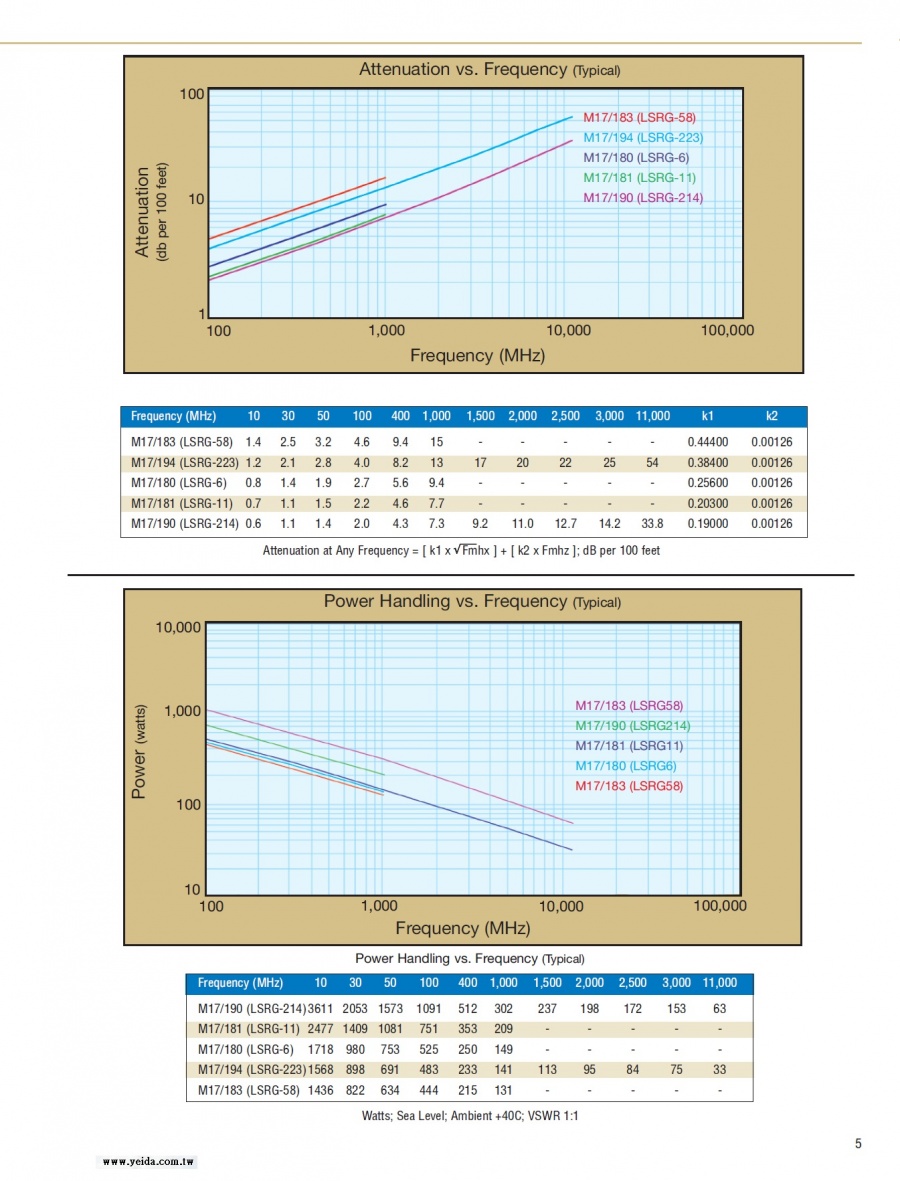

Attenuation and Structural Return Loss

MIL-C-17 specifications require that attenuation and structural

return loss (VSWR) be completely tested by sweeping 22

different 50 ohm cables over the frequency band for which their

use is recommended. Variance in materials or in the manufacturing

process can cause periodic discontinuities along a length

of coaxial cable, which can introduce resonance peaks (spikes).

These spikes occur when the discontinuities or changes in

electrical characteristics are periodic and at half-wave

distances.

When impedance changes occur periodically, there are frequencies

in which all of the reflections are in phase, resulting in

a large reflected signal or VSWR of the cables and their connectors.

Periodic reflections can also cause substantial increase

in attenuation at the resonance peaks. In the past, it was very

unusual to detect these narrow band, high attenuation spikes,

when cables were tested for attenuation using the older MIL-C-

17D discrete frequency test procedure (generally at 400 MHz

and 3 GHz and also at 10 GHz for RG-214).

Now, however, M17/190-RG214 has continuous swept maximum

VSWR and attenuation requirements from 50 MHz to 11

GHz. The maximum VSWR is 1.15:1 (23 dB SRL) at 100 MHz

increasing to 60 dB/100 feet at 11 GHz.

Coaxial cables that do not require "full band" swept frequency

performance can be procured under separate part numbers

in an unswept version. The specifications sheets for these

unswept cables recommend that they not be used above 400

MHz. The user must decide which cables will best suit the situation

based on cost, application and potential for system growth

and improvement.

MIL-C-17 QPL Listing

Only qualified cables should be used for military contracts.

All manufacturers of MIL-C-17 cables must obtain qualification

approval for their cables. The qualified products are then listed

in QPL-17, which is updated periodically throughout the year.

Please note that all RG numbered cables have been cancelled

from MIL-C-17 and only cables with part numbers starting

"MIL/17" should be used for new military contracts. Since

Qualification Inspections MIL-C-17 Requirements Typical MIL-C-17(G)

Critical to MIL-C-17(G) Inspection Results

Flame Propagation (IEEE-383) 8 Foot Maximum Burn Pass

Acid Gas Generation 2.0 Maximum 0.20

Halogen Content .20 Maximum 0.06%

Smoke Index (NES 711) 25.0 Maximum 11.4

Toxicity Index (NES 713) 5.0 Maximum < 2.2

Weathering 75% Minimum Retention Pass

Abrasion Resistance 75 Cycles Minimum 175 Cycles

Tensile Strength 1300 psi Minimum 1800 psi

Elongation 160% Minimum 200%

Fluid Resistance 50% Minimum Retention Pass

Heat Distortion 30%Maximum 10%

there is no longer any control of "RG" specifications, many cables

on the market with RG designations may be completely different in

construction and performance.

Special Designs

Although MIL-C-17 covers a broad range of cable types, Times

can also provide technical assistance in designing specialized shipboard

cables to meet specific system parameters that cannot be met

with existing MIL-C-17 cables. Please contact our Engineering

Department for assistance with your specialized applications.

|

.jpg)

Times-LSRG

2024/5/9 上午 04:44:55

2024/5/9 上午 04:44:55