-

產品搜尋

首頁 > 宜大-光纖專區(Optical Fibers)> 塑膠光纖Plastic optical fiber > Eska-BH High-Temp heat resistant 耐高溫塑膠光纖被覆線

ESKA-BH4001

1. Scope

The specification covers basic requirements for the structure and optical performances of BH-4001.

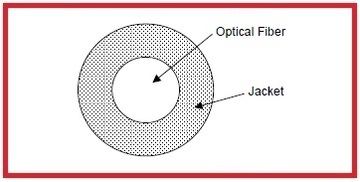

2. Structure

Table 1

3. PerformancesItem Specification Unit Min. Typ. Max. Optical Fiber Core Material - Polymethyl-Methacrylate Resin Cladding Material - Fluorinated Polymer Core Refractive Index - 1.49 Refractive Index Profile - Step Index Numerical Aperture - 0.58 Core Diameter um 920 980 1,040 Cladding Diameter um 940 1,000 1,060 Jacket Material - Crosslinked Polyethylene Color - Black Diameter Mm 2.13 2.18 2.23 Approximate Weight g/m 4 Indication on the Product - None

Table 2

All test are carried out under temperature of 25℃ unless otherwise specifiedItem Acceptance Criterion

and/or

[Test Condition]Specification Unit Min. Typ. Max. Maximum

RatingStorage

TemperatureNo Physical Deterioration

[in a Dry Atmosphere]℃ -55 - +105 Operation

TemperatureNo Deterioration

In Optical Properties*

[in a Dry Atmosphere]℃ -55 - +105 No Deterioration

in Optical Properties**

[under 95%RH condition]℃ - - +85 Optical

PropertiesTransmission Loss

[650nm Collimated Light][25℃ 50%RH] dB/km - - 200 [Operation Temperature] dB/km - - 250 Mechanical Characteristics Minimum Bend Radius Loss Increment ≦0.5dB

[A Quarter Bend]mm 15 - - Repeated Bending Endurance Loss Increment≦1dB

[in Conformity to the

JIS C 6861]***Times 1,000 - - Tensile Strength Tensile Force at 5% Elongation; [in Conformity to the JIS C 6861] N 70 - - Twisting Endurance Loss Increment≦1dB

[Sample Length : 1m

Tensile Force : 4.9N]Times 5 - - Impact Endurance Loss Increment≦1dB

[in Conformity to the

JIS C 6861]Nm 0.4 - -

* Attenuation change shall be within +/- 10% after 1,000 hours.

** Attenuation change shall be within +/- 10% after 1,000 hours, except that due to absorbed water.

*** Bend Angle +/-90。,Bend Radius 15mm, Tension 500g.

2025/11/1 上午 06:52:38

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司