商品編號: Belden-29543

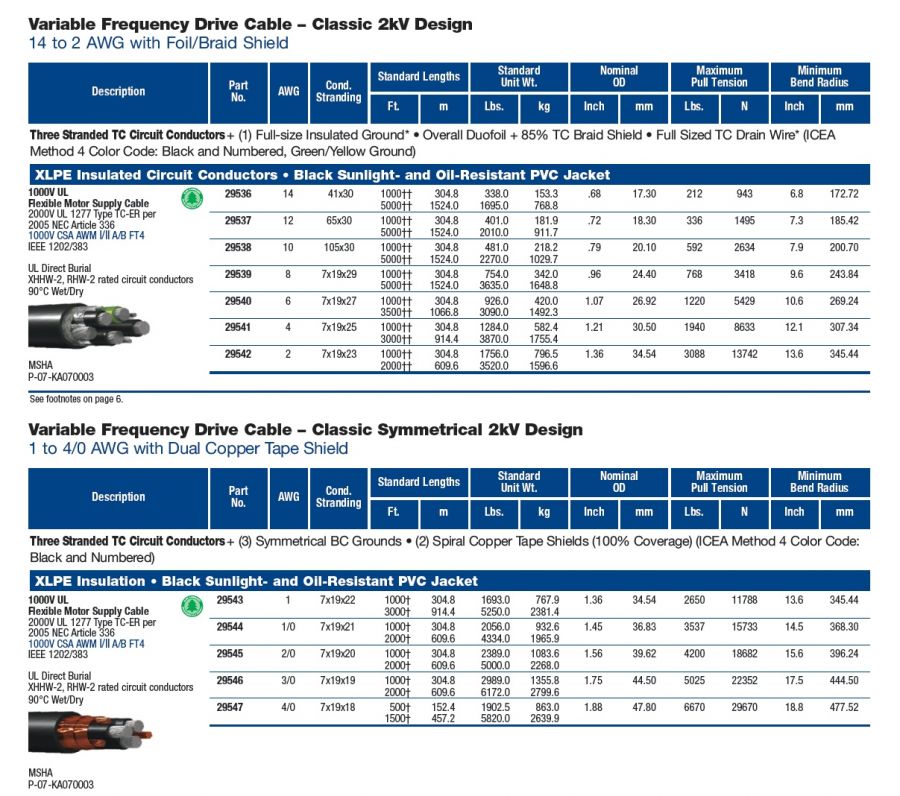

Belden-(29543, 29544, 29545, 29546, 29547) VFD Cable – Classic Symmetrical 2kV Design 1 to 4/0 AWG with Dual Copper Tape Shield (變頻馬達控制線)

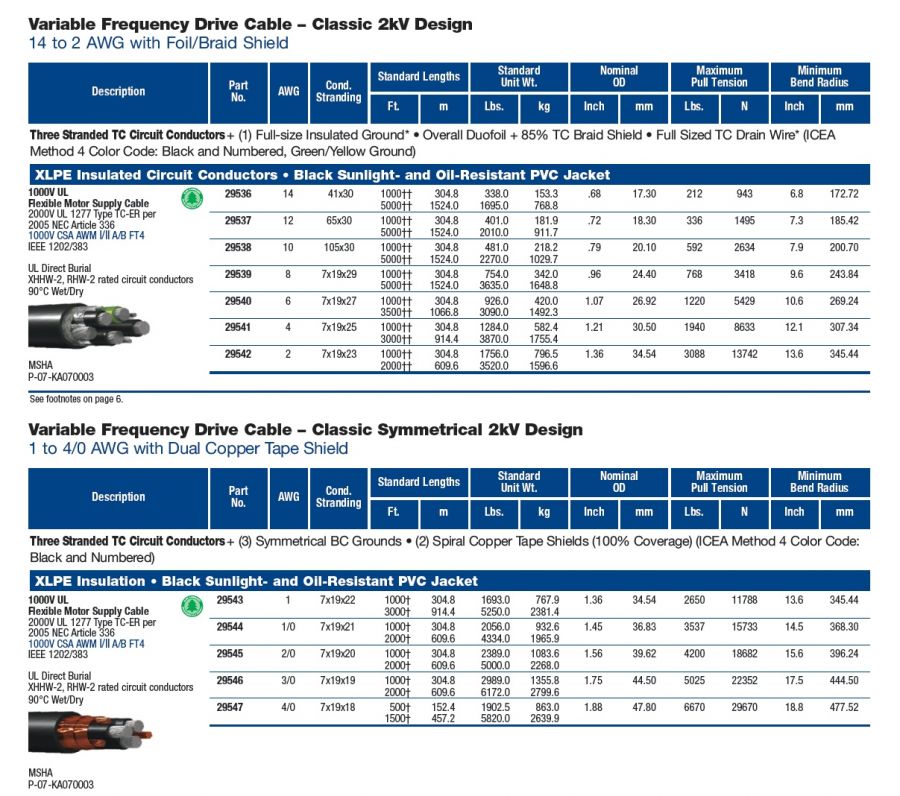

Variable Frequency Drive Cable – Classic Symmetrical 2kV Design

1 to 4/0 AWG with Dual Copper Tape Shield

Three Stranded TC Circuit Conductors+ (3) Symmetrical BC Grounds • (2) Spiral Copper Tape Shields (100% Coverage) (ICEA Method 4 Color Code:

Black and Numbered)

XLPE Insulation • Black Sunlight- and Oil-Resistant PVC Jacket

Variable frequency AC motor drive output cables

are subject to harsh operating environments

characterized by high voltage spikes, high noise

levels and adverse environmental conditions.

Typical cabling solutions for this application have

been unshielded tray cables, single-conductor lead

wire installed in conduit or continuously-welded

armored cable. These solutions suffer from complex,

costly installation and potential reliability problems.

Belden Variable Frequency Drive (VFD) Cables

were designed and engineered to overcome

these challenges.

The Challenge of VFD Applications

VFD cables carry power from AC drive systems to

AC motors. As a result, these cables must handle

not only the overall high power levels of the

pulse-width modulated (PWM) signals, but also

the extremely high voltage which can occur when

standing waves develop on the conductors. This

high voltage can cause corona discharge between

the conductors of conventional cables, causing

damage not only to the cabling itself, but also

to the motors, bearings, drives and related

equipment. In turn, this damage can cause failure

of the entire drive system, resulting in costly

production downtime.

Limitations of Conventional VFD Cables

In addition to experiencing failures due to corona

discharge and adverse environmental conditions,

conventional cabling is difficult and expensive to

install. Armored cable and lead wire in conduit are

cumbersome and heavy and require extremely large

installation bending radii, making installation both

time-consuming and labor intensive. Yet they still

do not solve noise and corona dishcarge problems,

nor do they effectively address the high levels of

noise generated by VFDs.

The Belden VFD Solution

Only Belden's series of VFD Cable in gauge sizes

from 16 to 4/0 provide the robust construction

required to deliver superior electrical performance

and reliability, even in the most demanding

industrial environments.

Thicker, Industrial-grade

XLPE Insulation

• Provides more stable electrical

performance than PVC

• Lower capacitance resulting in

- Longer cable runs

- Reduced peak motor terminal

voltage for extended motor life

- Reduced likelihood of corona discharge

- Reduced magnitude of standing waves

- Increased efficiency of power transfer

High-strand Tinned Copper

Circuit Conductors

• More flexible for ease of installation

• Better vibration resistance

• Numbered for ease of identification

Industrial-grade PVC or Haloarrest

Low Smoke Zero Halogen Jackets

• Sunlight Resistant

• Oil Resistant (PVC only)

Certified to Numerous Safety Standards

(Ratings Vary by Construction)

• 1000V UL Flexible Motor Supply

• 600V or 2000V UL1277 Type TC-ER

per 2005 NEC Article 336

• 1000V CSA AWM I/II A/B FT4

• MSHA

• 90°C Wet/Dry

• Class I & II; Division 2

hazardous locations

• UL1685 Vertical Tray Flame Test

• IEEE 1202/383 Vertical Tray flame test

at 70,000 BTU/hour

• UL Direct Burial

• RoHS compliant

• CE approved

Product Cross Reference

Belden VFD cable performance supports AC drives

manufactured by the following companies:

Rockwell Automation, AA Electric, ABB, Baldor,

Cutler-Hammer, Emerson Process Management,

Fivestar Electric Motors, General Electric, Hitachi,

Magnetek, Mitsubishi Electric Automation, Motion

Industries, Quality Drive Systems, Robicon, Siemens,

Square D, Toshiba and TB Woods.

Product Availability

Belden Variable Frequency Drive cables are available

in various standard lengths. Armored versions are

also available. And now, with Belden offering VFD

cables in a wider range of gauges, drive manufacturers

have more options than ever before in specifying

the appropriate sizes for their specific applications.

Encoder and Signal Cables

Belden also offers the following standard cables

for encoder applications. Encoder cables help feed

information to the microprocessor regarding both

the speed and the position of the rotor. Signal

cable can be used for brake or thermal

contact applications.

Part Number Pairs AWG

8790 (Power Supply) 1 18

9729 (Encoder) 2 24

9730, 89730 (Encoder) 3 24

9728 (Encoder) 4 24

9892 (Encoder) 4 20

9860 (Signal) 1 16

|

5344535

2026/2/4 下午 01:04:48

2026/2/4 下午 01:04:48