商品編號: ANIXT-MIL-C-17-COAX

商品編號: ANIXT-MIL-C-17-COAX

MIL-C-17-COAX RG Mil-Spec Coaxial Cables RG型美軍規同軸電纜

CROSS REFERENCE

SWEPT TO UNSWEPT

MIL-SPEC COAXIAL CABLE TYPES

SWEPT UNSWEPT

MIL-C-17/28 RG58 MIL-C-17/155 RG58

MIL-C-17/52 RG119, 120 MIL-C-17/156 RG119, 120

MIL-C-17/54 RG122 MIL-C-17/157 RG122

MIL-C-17/60 RG142 MIL-C-17/158 RG142

MIL-C-17/65 RG165, 166 MIL-C-17/159 RG165, 166

MIL-C-17/67 RG177 MIL-C-17/160 RG177

MIL-C-17/72 RG211 MIL-C-17/161 RG211

MIL-C-17/73 RG212 MIL-C-17/162 RG212

MIL-C-17/74 RG213, 215 MIL-C-17/163 RG213, 215

MIL-C-17/75 RG214, 365 MIL-C-17/164 RG214, 365

MIL-C-17/78 RG217 MIL-C-17/165 RG217

MIL-C-17/79 RG218, 219 MIL-C-17/166 RG218, 219

MIL-C-17/84 RG223 MIL-C-17/167 RG223

MIL-C-17/92 RG115 MIL-C-17/168 RG115

MIL-C-17/93 RG178 MIL-C-17/169 RG178

MIL-C-17/111 RG303 MIL-C-17/170 RG303

MIL-C-17/112 RG304 MIL-C-17/171 RG304

MIL-C-17/113 RG316 MIL-C-17/172 RG316

MIL-C-17/119 RG174 MIL-C-17/173 RG174

MIL-C-17/127 RG393 MIL-C-17/174 RG393

MIL-C-17/128 RG400 MIL-C-17/175 RG400

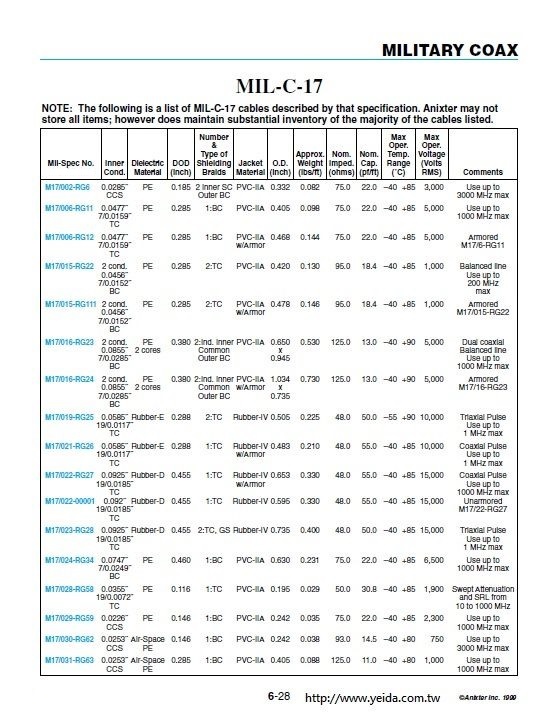

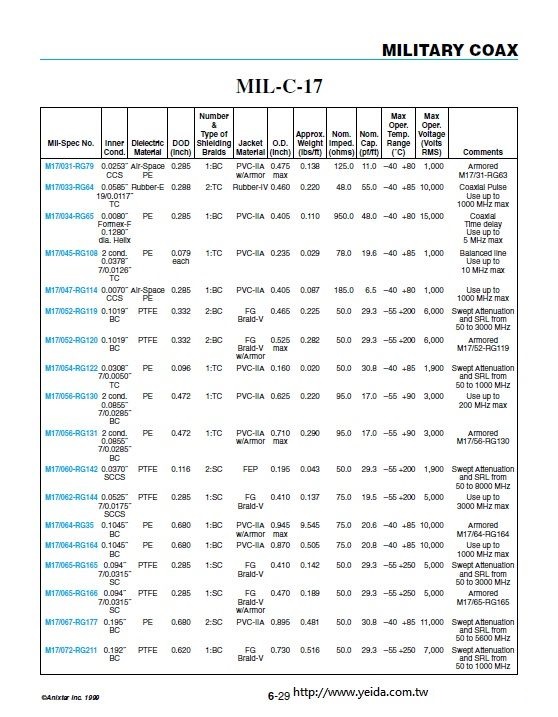

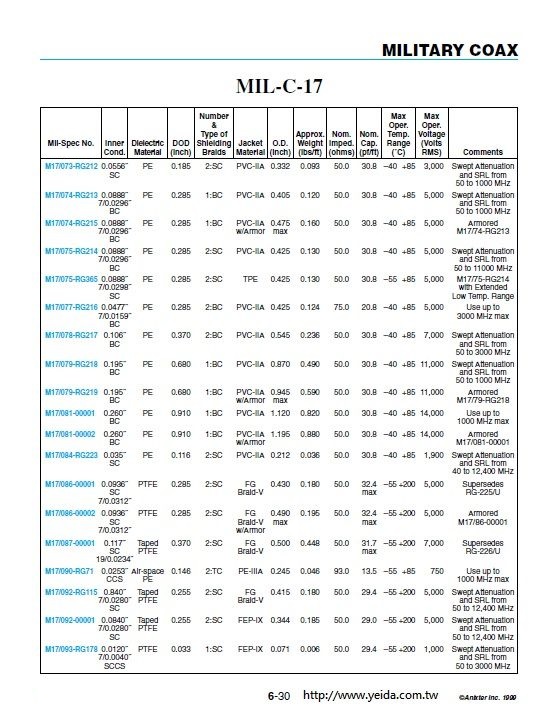

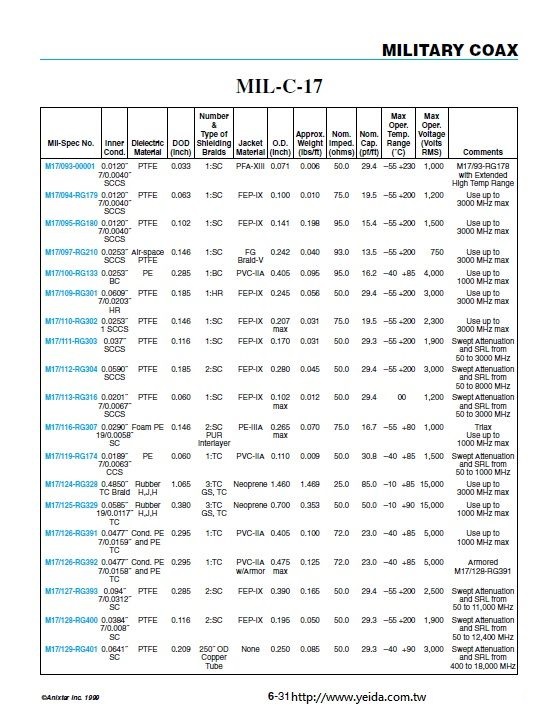

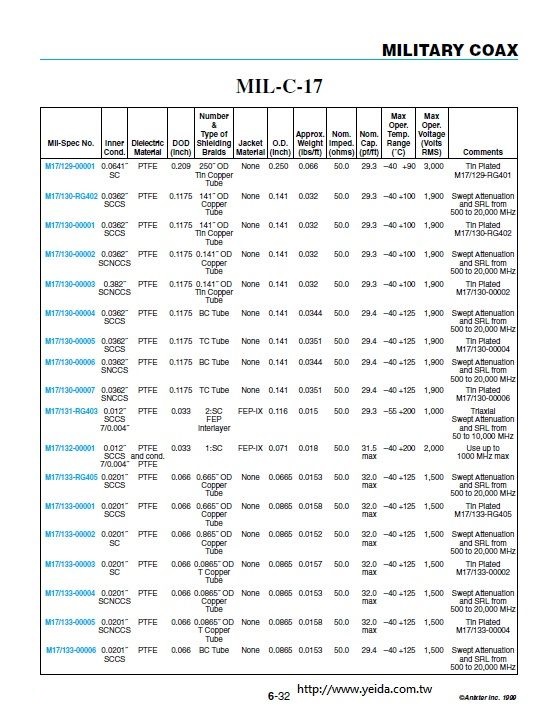

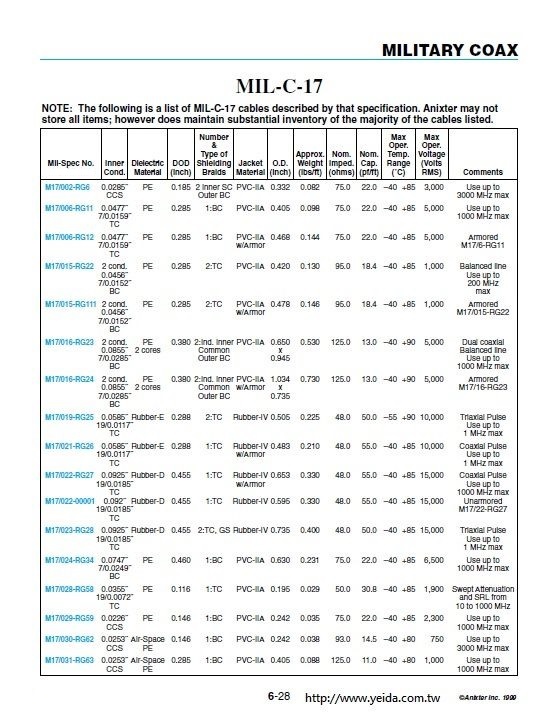

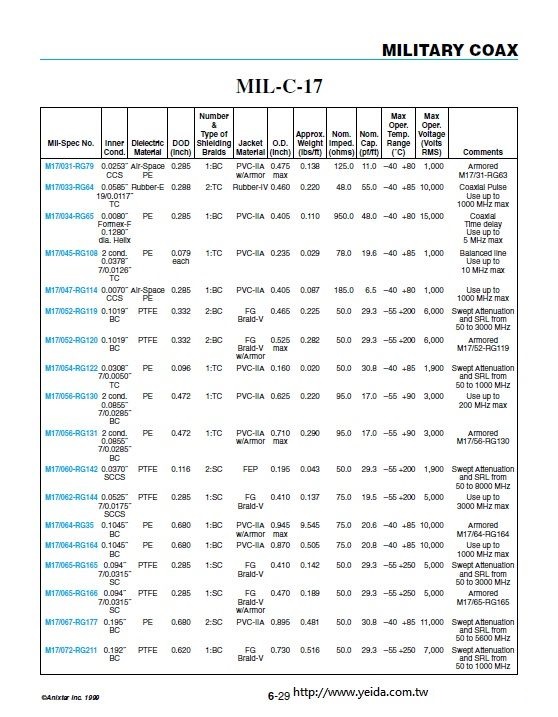

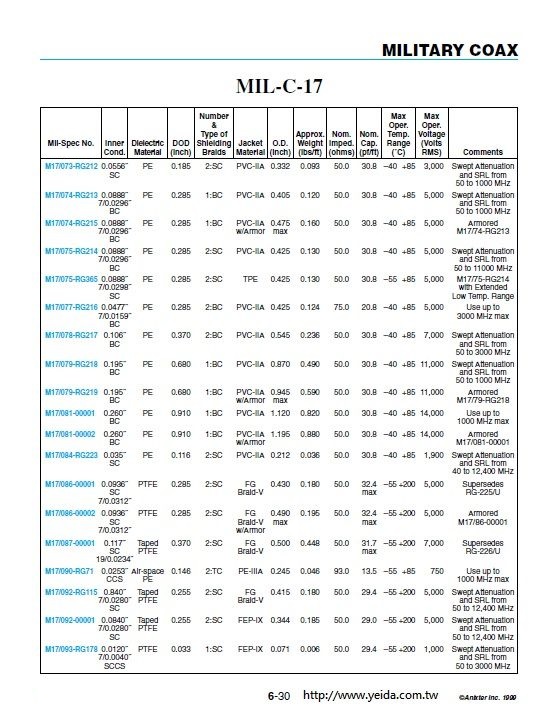

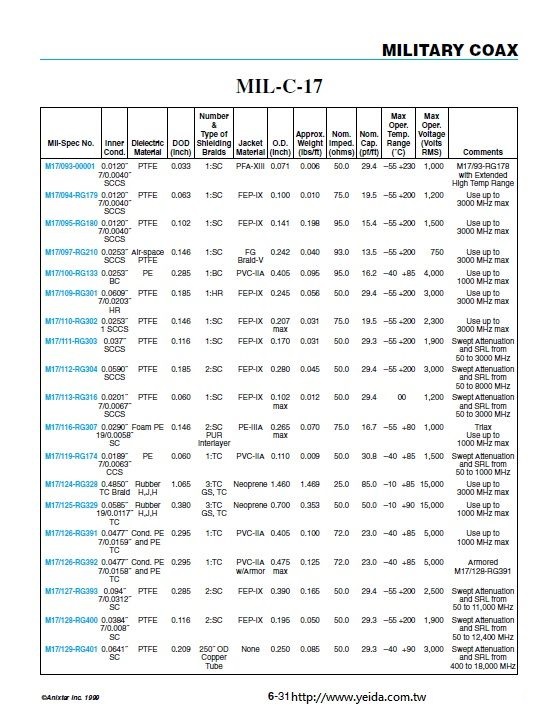

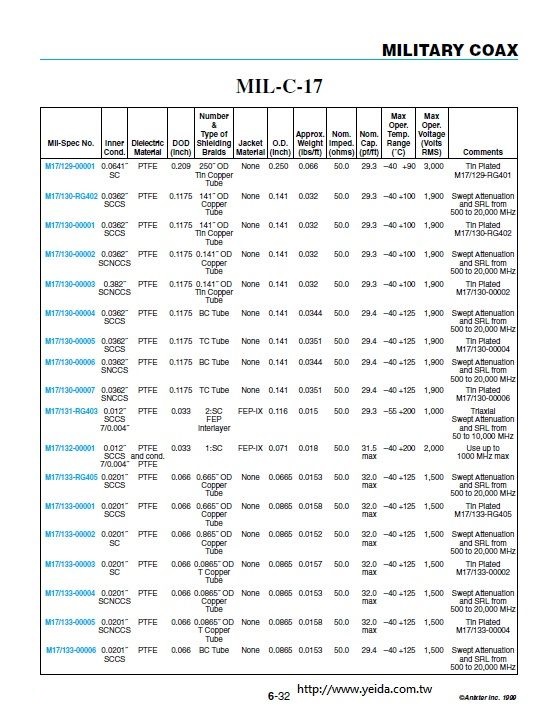

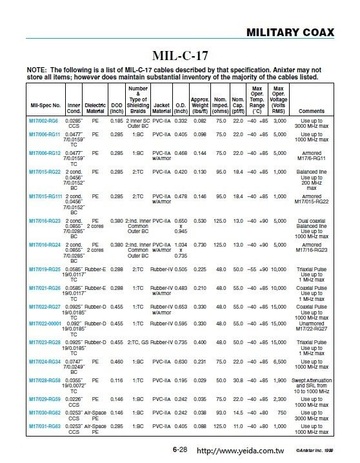

MIL-C-17

INTRODUCTION:

MIL-C-17 is the government specification used to standardize Mil-Spec Coaxial Cables. The “RG” part numbers

have been superseded by M-17 part numbers. The most recent revision to MIL-C-17 is the revision “G.” Cables

to this revision are available in swept or unswept frequency measurements and Low Smoke jackets. Cables

must be procured from QPL sources when QPL listing exists.

APPLICATIONS:

Radio frequency coaxial cables conforming to military specifications.

Benefits in Using MIL-C-17 Coaxial Cables: In 1976, Revision “E” to MIL-C-17 was released to better define

the electrical and mechanical properties for Mil-Spec Coaxial Cables. The most important changes for 50

ohm cables were the addition of swept frequency measurements of both structural return loss (VSWR) and

attenuation. Before Revision “E” there were no (VSWR) requirements and the attenuation requirements were

only given at two or three frequencies.

Adhesion Requirements: Prior to Revision “E” it was possible in shorter cable lengths to pull the center

conductor out of the body of the entire assembly during the stripping operations, or there could be too much

adhesion between the core and the center conductor causing the conductor to break before the dielectric

could be stripped off. M-17 specifications now contain maximum and minimum adhesion requirements of the

dielectric core and center conductor.

Dimensional Stability: Temperature extremes can cause shrinkback of the cable jacket which can create

a poor termination. All cables manufactured and tested to Revision “E” have specified maximum shrinkback

allowance for the dielectric core and jacket.

Stress-Crack Resistance: A stress-crack resistance test is now required under M-17 on all FEP (fluorinated

ethylene propylene) and PFA (penfloraolkoxy) jacketed cables. This test identifies cables with previously

undetected residual stress that could result in jacket cracking.

Contamination: M-17 Revisions “F” and “G” have completely replaced Type IA PVC with Type IIA PVC, a

noncontamination compound. The plasticizers in Type IA PVC jackets can penetrate the braid shield and

migrate into the polyethylene dielectric core causing a large increase in the dielectric loss portion of attenuation.

Coaxial cables with a Type IA PVC jacket can affect other cables in close contact even if the other cables

have a Type IIA jacket.

Attenuation and Structural Return Loss: A (VSWR) attenuation and structural return loss test is required

under M-17 Revisions “F” and “G.” This test is performed by sweeping each of the twenty-two (22) different

50 ohm coaxial cables over the frequency band for which their use is recommended. In the past, using the

older MIL-C-17 Revision “D” tests, it was very unusual to detect these narrow band, high attenuation spikes.

Coaxial cables that do not require “full band” swept frequency performance can be procured under separate part

numbers in an unswept version. The specification sheets for these unswept cables recommended they

not be used above 400 MHz. The end user or “OEM” must decide which cables will best suit the situation

and application.

MIL-C-17 QPL Listing and Cable Designations: M-17 Coaxial Cables must pass rigorous inspection and

qualification tests in order to obtain QPL listing, thus insuring consistent high-quality cables. Cables that are

manufactured to MIL-C-17 specification no longer carry the RG designation. Instead, they are marked with

M-17 designation. In the future, any new cable design will be designated by an M-17 part number. Only the

qualified military cables (QPL listed) are authorized to be marked with the military number after the proper

testing and requirements are met as specified in MIL-C-17 and applicable slash sheets. Radio frequency cables,

which are not qualified (QPL) to MIL-C-17 cannot be marked with the military specification part number (“M-17”)

and the word type either preceding or following the military part number. In addition to M-17 numbers, all

cables are marked with the manufacturer’s name and government identification number. Cables that are not

marked with all of this information are not qualified and there is no guarantee of their performance.

MIL-C-17

ABBREVIATIONS

DIELECTRIC

FEP . . . . . . . . . . . . . . . . . .Fluorinated Ethylene Propylene (Solid)

PE . . . . . . . . . . . . . . . . . . .Polyethylene (Solid)

PIB . . . . . . . . . . . . . . . . . .Polyisobutylene, Type B, per MIL-C-17D

PS . . . . . . . . . . . . . . . . . . .Polystyrene

PTFE . . . . . . . . . . . . . . . .Polytetrafluoroethylene (Solid)

Rubber . . . . . . . . . . . . . . .per MIL-C-17

CONDUCTORS & BRAID MATERIALS

AL . . . . . . . . . . . . . . . . . . .Aluminum

BC . . . . . . . . . . . . . . . . . . .Bare copper

BCCS . . . . . . . . . . . . . . . .Bare copper covered steel

BerC . . . . . . . . . . . . . . . . .Beryllium-Copper Alloy

CCA . . . . . . . . . . . . . . . . .Copper covered aluminum

CCS . . . . . . . . . . . . . . . . .Copper covered steel

GS . . . . . . . . . . . . . . . . . .Galvanized steel

HR . . . . . . . . . . . . . . . . . .High resistance wire

NC . . . . . . . . . . . . . . . . . .Nickel coated copper

SC . . . . . . . . . . . . . . . . . . .Silver covered copper

SCBerC . . . . . . . . . . . . . .Silver covered Beryllium-Copper Alloy

SCCadBr . . . . . . . . . . . . .Silver covered cadmium bronze

SCCS . . . . . . . . . . . . . . . .Silver covered copper covered steel

SSC . . . . . . . . . . . . . . . . .Silver covered strip

TC . . . . . . . . . . . . . . . . . . .Tinned copper

TCCS . . . . . . . . . . . . . . . .Tinned copper covered steel

JACKET MATERIAL

CLP . . . . . . . . . . . . . . . . . .Cross-linked polyethylene

E-CTFE-X . . . . . . . . . . . . .Ethylene/Chlorotrifluoroethylene Copolymer

ETFE-X . . . . . . . . . . . . . . .Ethylene/Tetrafluoroethylene Copolymer

FEP-IX . . . . . . . . . . . . . . .Fluorinated Ethylene Propylene, Type IX, per MIL-C-17

FG Braid-V . . . . . . . . . . . .Fiberglass, impregnated, Type V, per MIL-C-17

HDPE . . . . . . . . . . . . . . . .High density polyethylene

PE-II . . . . . . . . . . . . . . . . .Clear polyethylene

PE-IIIA . . . . . . . . . . . . . . .High molecular weight, black polyethylene, Type IIIA, per MIL-C-17

PFA-XIII . . . . . . . . . . . . . .Perfluoroalkoxy, per MIL-C-17

PTFE . . . . . . . . . . . . . . . .Polytetrafluoroethylene, per MIL-C-17

PUR . . . . . . . . . . . . . . . . .Polyurethane, Black specific compounds

PVC-I . . . . . . . . . . . . . . . .Black polyvinyl chloride, contaminating, Type I, per MIL-C-17D

PVC-II . . . . . . . . . . . . . . . .Grey polyvinyl chloride, noncontaminating, Type II, per MIL-C-17D

PVC-IIA . . . . . . . . . . . . . . .Black polyvinyl chloride, noncontaminating, Type IIA, per MIL-C-17

Rubber . . . . . . . . . . . . . . .Per MIL-C-17

Sil/DAC-VI . . . . . . . . . . . .Dacron braid over silicon rubber, Type VI, per MIL-C-17

TPE . . . . . . . . . . . . . . . . . .Thermoplastic Elastome

|

5267272

2026/3/7 下午 05:22:23

2026/3/7 下午 05:22:23