BFOU-HCF 11000C (NEK 606 P34)

HALOGEN FREE, FIRE RESISTANT, FLAME RETARDANT, MUD RESISTANT POWER CABLE

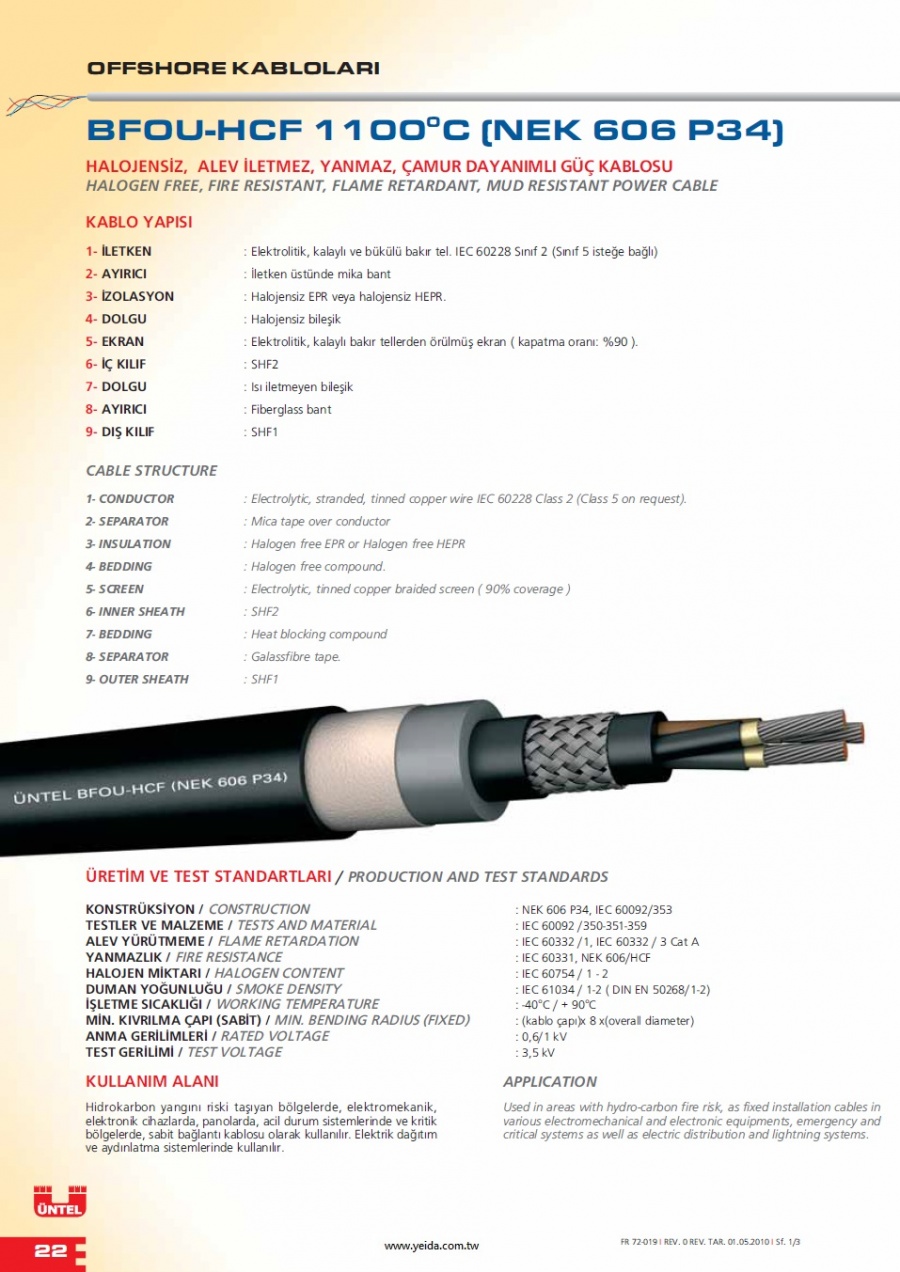

CABLE STRUCTURE

1- CONDUCTOR : Electrolytic, stranded, tinned copper wire IEC 60228 Class 2 (Class 5 on request).

2- SEPARATOR : Mica tape over conductor

3- INSULATION : Halogen free EPR or Halogen free HEPR

4- BEDDING : Halogen free compound.

5- SCREEN : Electrolytic, tinned copper braided screen ( 90% coverage )

6- INNER SHEATH : SHF2

7- BEDDING : Heat blocking compound

8- SEPARATOR : Galassfibre tape.

9- OUTER SHEATH : SHF1

PRODUCTION AND TEST STANDARDS

CONSTRUCTION : NEK 606 P34, IEC 60092/353

TESTS AND MATERIAL : IEC 60092 /350-351-359

FLAME RETARDATION : IEC 60332 /1, IEC 60332 / 3

FIRE RESISTANCE : IEC 60331, NEK 606/HCF

HALOGEN CONTENT : IEC 60754 / 1 - 2

SMOKE DENSITY : IEC 61034 / 1-2 ( DIN EN 50268/1-2)

WORKING TEMPERATURE : -40°C / + 90°C

MIN. BENDING RADIUS (FIXED) : 8 x(overall diameter)

RATED VOLTAGE : 0,6/1 kV

TEST VOLTAGE : 3,5 kV

APPLICATION

Used in areas with hydro-carbon fire risk, as fixed installation cables in various electromechanical and electronic equipments, emergency and critical systems as well as electric distribution and lightning systems.

ENVIRONMENT

Usable at all conditions in marine environment such as dry, wet or oily locations.

SAFETY

Even at direct contact with a 1100 oC hydro-carbon fire, it will sustain the connection for as long as stated in NEK606 standard. That provides necessary equipment (fire alarm and extinguishing systems, water pumps, communication, radio, control systems, lightning, etc.) to work uninterrupted during a fire. Due to its halogen free and flame retardant features, it wont create corrosive gases and prevents the fire from spreading around as well. Thus it protects human life and equipment, during a fire and helps extinguishing the fire. Low smoke density reduces the risk of suffocation and keeps visibility around the fire zone.

30197804

2026/1/18 下午 01:22:25

2026/1/18 下午 01:22:25