商品編號: LAPP-OLFLEX-TORSION-FRNC , google, yahoo, msn, belden

LAPP-ÖLFLEX® TORSION FRNC Cold- and oil resistant cables for flexible application under torsional load, halogen free - 0,6/1 kV 風力發電用線

The special construction compensates reliably the permanent torsional movements inside of windmills between the nacelle and the tower; The high flexibility and the good dismantle and stripping properties enable easy space- saving cable installation and fast processing; Saltwater resistant for On- and Off-Shore application; FRNC = Flame Retardant Non Corrosive - Reduction of flame propagation and density and toxicity of smoke gases in event of fire - Minimisation of damage to buildings and production facilities - Safety for maintenance staff resp. in areas with high personnel concen- tration; The copper wrapping of the screened D version protects against electromagnetic interference

Application range

- For fixed, flexible as well as for torsional moved applications in the field of machinery building and wind power plant engineering

- Especially for the drip loop installation between the rotating nacelle and the stationary windmill tower to connect the generator and control units

- As torsional moved cable for application in North America with UL WTTC Listing (Wind Turbine Tray Cable) we recommend ÖLFLEX® FORTIS which complies to the NFPA 79 standard resp. UL 2277 and UL 6140 outline

| 1150199 |

12 G 0,75 |

12,4 |

86.4 |

237 |

|

| 1150377 |

14 G 0,75 |

13.0 |

100.8 |

291 |

|

| 1150201 |

18 G 0,75 |

14,6 |

129.6 |

323 |

|

| 1150204 |

25 G 0,75 |

17,8 |

180.0 |

480 |

|

| 1150208 |

50 G 0,75 |

24,2 |

360.0 |

886 |

|

| |

| 1150373 |

12 G 1,0 |

13,2 |

115.2 |

274 |

|

| 1150378 |

16 G 1,0 |

14,8 |

153.6 |

392 |

|

| |

| 1150271 |

3 G 1,5 |

9.0 |

43.2 |

131 |

|

| 1150272 |

4 G 1,5 |

9,7 |

57.6 |

156 |

|

| 1150273 |

5 G 1,5 |

10,6 |

72.0 |

183 |

|

| 1150275 |

7 G 1,5 |

12,6 |

100.8 |

253 |

|

| 1150279 |

12 G 1,5 |

15,3 |

172.8 |

386 |

|

| 1150280 |

18 G 1,5 |

18,3 |

259.2 |

563 |

|

| 1150374 |

25 G 1,5 |

22,8 |

360.0 |

837 |

|

| 1150375 |

32 G 1,5 |

24,5 |

460.8 |

994 |

|

| |

| 1150311 |

3 G 2,5 |

10,4 |

72.0 |

181 |

|

| 1150312 |

4 G 2,5 |

11,3 |

96.0 |

242 |

|

| 1150313 |

5 G 2,5 |

12,4 |

120.0 |

258 |

|

| 1150315 |

7 G 2,5 |

15.0 |

168.0 |

372 |

|

| 1150319 |

12 G 2,5 |

18,9 |

288.0 |

567 |

|

| 1150322 |

19 G 2,5 |

23,9 |

456.0 |

925 |

|

| 1150376 |

25 G 2,5 |

26,8 |

600.0 |

1183 |

|

| |

| 1150350 |

3 G 4 |

11,9 |

115.2 |

254 |

|

| 1150351 |

4 G 4 |

13.0 |

153.6 |

313 |

|

| 1150352 |

5 G 4 |

14,3 |

192.0 |

370 |

|

| |

| 1150355 |

3 G 6 |

12,9 |

173.0 |

338 |

|

| 1150356 |

4 G 6 |

14,4 |

230.4 |

401 |

|

| 1150357 |

5 G 6 |

16.0 |

288.0 |

486 |

|

| |

| 1150360 |

3 G 10 |

16,6 |

288.0 |

556.1 |

|

| 1150361 |

4 G 10 |

18,4 |

384.0 |

658 |

|

| 1150362 |

5 G 10 |

20,5 |

480.0 |

799 |

|

| |

| 1150366 |

4 G 16 |

22,2 |

614.4 |

1061 |

|

| 1150367 |

5 G 16 |

24,4 |

768.0 |

1188 |

|

| |

| 1150371 |

4 G 25 |

26,9 |

960.0 |

1526 |

|

| 1150372 |

5 G 25 |

29,9 |

1200.0 |

1881 |

|

| |

| 1150369 |

5 G 35 |

33,7 |

1680.0 |

2520 |

|

| |

| 1150379 |

5 G 50 |

39,5 |

2400.0 |

3710 |

|

Footnote:

All product related values as shown are nominal values unless specified differently. Further values, e.g. tolerances we submit on request - if available and released for publication.

Copper price basis: EUR 150 / 100 kg; For utilization and definition of 'Metal price basis' and 'Metal index' see Appendix T17

Packaging size: Coil ≤ 30 kg and ≤ 250 m, otherwise drum

Please specify the desired packaging size (e.g. 1 x 500 m drum or 5 x 100 m coils)

Photographs are not to scale and do not represent detailed images of the respective products. |

Technical Data

- Core identification code

Control and connection cables: Colour coded according to VDE 0293-308, see Appendix T9 Starting at 6 cores: Black with white numbers

Paired signal cables: DIN 47100

- Approvals

UL AWM Style 21288 cUL AWM II A/B

- Specific insulation resistance

> 20 GOhm x cm

- Conductor stranding

Extra fine wire in acc. to VDE 0295 Cl.6 / IEC 60228 Cl.6

(For matching US conductor sizes according AWG please see technical table T16)

- Minimum bending radius

Flexible use: 10 x outer diameter

Fixed installed: 6 x outer diameter

|

- Rated voltage

nach VDE: U0/U 0,6/1,0 kV

Working voltage acc. UL: 1000V

- Test voltage

C/C: 4000 V

- Protective conductor

G = with protective conductor GN/YE

X = without protective conductor

- Range of temperature

Flexible use: -40°C up to +90°C (UL +80°C)

Static use: -40°C up to +90°C (UL +80°C)

|

Design

- Extra fine wired conductor of plain copper

- Core insulation of LS0H polyolefin polymer

- Cores torsion optimized twisted into layers

- Optional screening (D) of helically tinned copper wire wrapping

- Outer sheath of halogen free special compound, colour black (RAL 9005)

Approvals (Norm references)

- UL AWM Style 21288 / cUL AWM II A/B

- Fire behaviour : - Halogen free (IEC 60754-1) - Corrosivity of gases (IEC 60754-2) - Smoke density (IEC 61034-2) - Flame retardant (IEC 60332-1-2) - No flame propagation (IEC 60332-3-24 resp. IEC 60332-3-25)

- Oil resistant acc. to EN 60811-2-1 and UL OIL RES I and UL OIL RES II

- UV-resistant according ISO 4892-2

- Ozone resistant according EN 50396

Product features

- Torsion-resistant up to ±150 °/mtr

- Good weather-, abrasion-, temperature- and UV resistance

- Resistant against a multitude of oils

- Halogen free and highly flame retardant

- Considering economic minimum quantities also customized designs are possible

LAPP OLFLEX® TORSION FRNC Cold- and oil resistant cables for flexible application under torsional load, halogen free - 0,6/1 kV風力發電用線

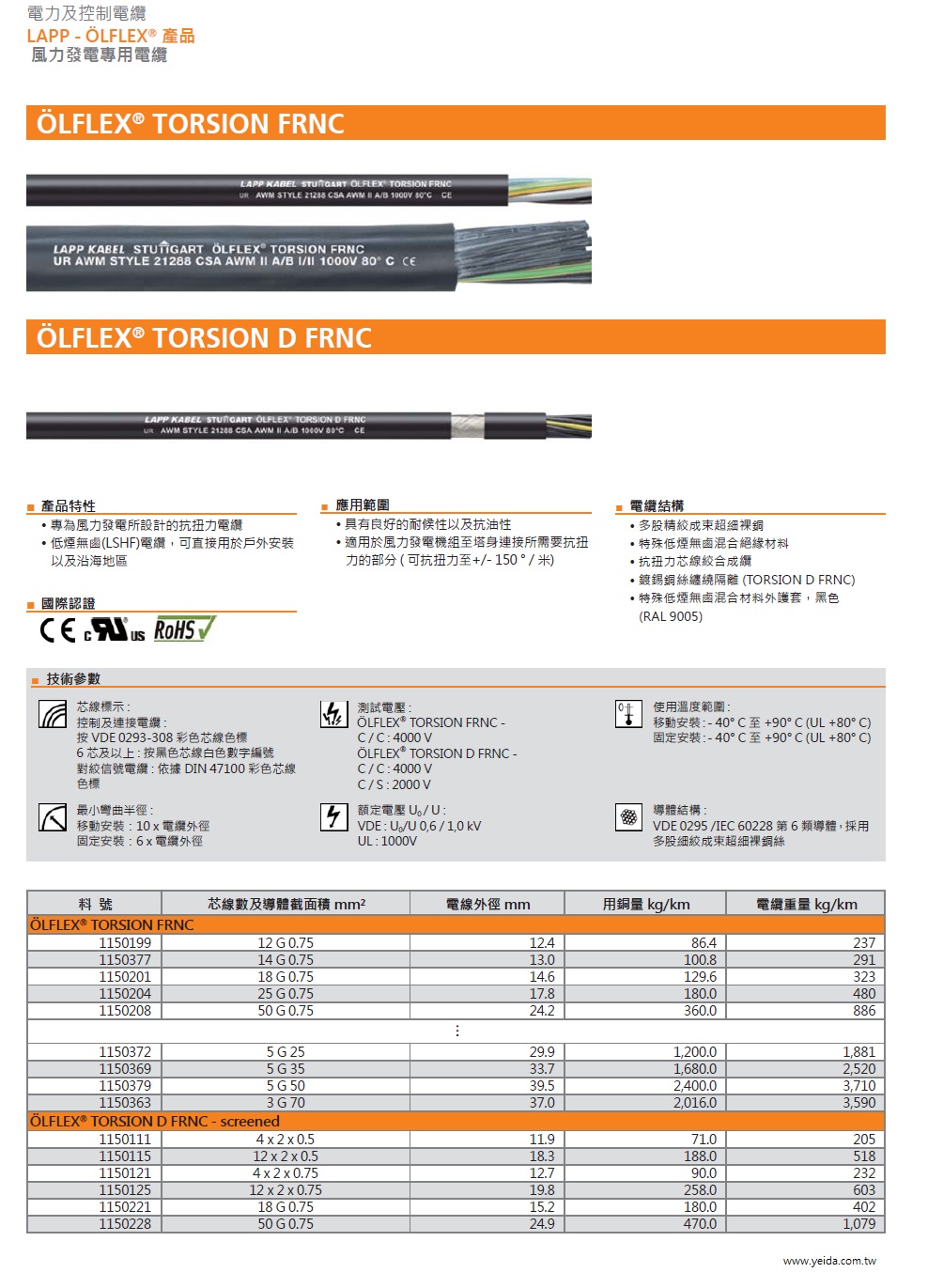

■ 產品特性

• 專為風力發電所設計的抗扭力電纜

• 低煙無鹵(LSHF)電纜,可直接用於戶外安裝

以及沿海地區

■ 國際認證 CE, UL, CSA, ROHS

■ 應用範圍

• 具有良好的耐候性以及抗油性

• 適用於風力發電機組至塔身連接所需要抗扭

力的部分 ( 可抗扭力至+/- 150 ° / 米)

■ 電纜結構

• 多股精絞成束超細裸銅

• 特殊低煙無鹵混合絕緣材料

• 抗扭力芯線絞合成纜

• 鍍錫銅絲纏繞隔離 (TORSION D FRNC)

• 特殊低煙無鹵混合材料外護套,黑色

(RAL 9005)

■ 技術參數

芯線標示:

控制及連接電纜:

按VDE 0293-308 彩色芯線色標

6 芯及以上: 按黑色芯線白色數字編號

對絞信號電纜: 依據DIN 47100 彩色芯線

色標

額定電壓U0 / U :

VDE : U0/U 0,6 / 1,0 kV

UL : 1000V

測試電壓 :

ÖLFLEX® TORSION FRNC -

C / C : 4000 V

ÖLFLEX® TORSION D FRNC -

C / C : 4000 V

C / S : 2000 V

導體結構 :

VDE 0295 /IEC 60228 第6 類導體,採用

多股細絞成束超細裸銅絲

最小彎曲半徑 :

移動安裝:10 x 電纜外徑

固定安裝:6 x 電纜外徑

使用溫度範圍:

移動安裝:- 40° C 至 +90° C (UL +80° C)

固定安裝:- 40° C 至 +90° C (UL +80° C)

|