商品編號: LAPP-OLFLEX-ROBUST-F1 ,google, belden, yahoo, igus

LAPP- ÖLFLEX® ROBUST F1 超柔移動式防水防油汙耐磨損扭曲機器手臂專用電纜 TPE-PUR robot cable, for flexing and torsion load, AWM- approval

TPE-PUR robot cable, for flexing and torsion load, AWM- approval

Space saving installation due to small cable diameters; Warehouse available High-Tec Robot cables!; Protected against water and dirt; Wear-resistant

Application range

- Plant engineering

- Multi-axis articulated robots

- Automated handling equipment

- In power chains or moving machine parts

Design

- Fine or superfine strands, 0.14mm² -0.5mm² made from tinned copper wires, above plain.

- Core insulation: TPE

- Core coding, see Appendix

- Cores (or core pairs) twisted in layers or bundles

- PTFE tape wrapping

- Pair screen (D): layer of tinned copper wires

- Polyurethane sheath (PUR), black (RAL 9005)

Approvals (Norm references)

- Usage in Power Chains: Please comply with the assembly guidelines Appendix T3

- For travel distances up to 100 m (horizontal)

- USA: Acc. NFPA79 Ed 08 in industrial machinery as part of a listed assembly only.

Product features

- Abrasion and cut resistant

- Hydrolysis-resistant

- Oil resistant

- Low adhesive surface

- Flame retardant

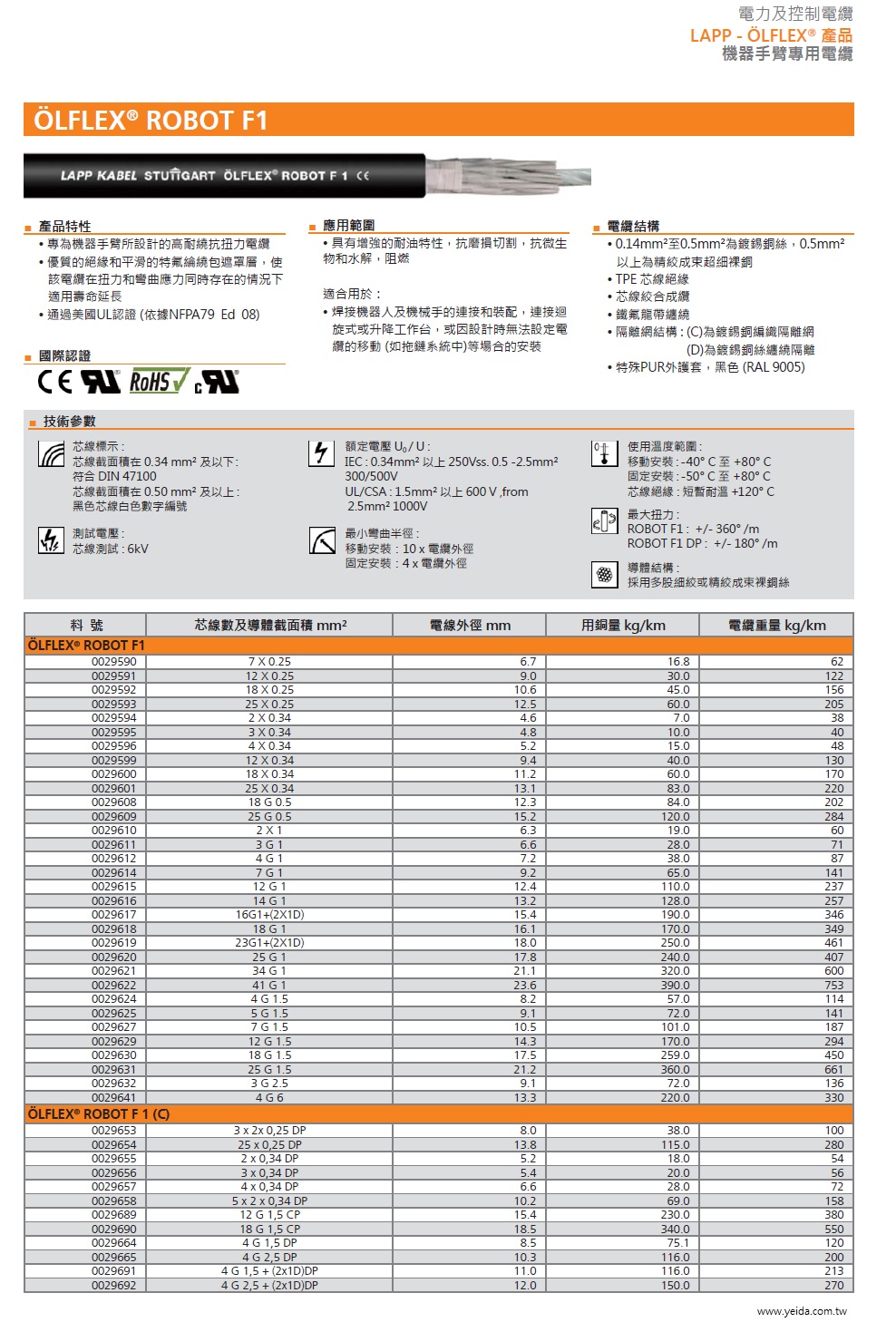

| 0029590 |

7 X 0,25 |

6,7 |

16.8 |

62 |

|

| 0029591 |

12 X 0,25 |

9 |

30 |

122 |

|

| 0029592 |

18 X 0,25 |

10,6 |

45 |

156 |

|

| 0029593 |

25 X 0,25 |

12,5 |

60 |

205 |

|

| 0029594 |

2 X 0,34 |

4,6 |

7 |

38 |

|

| 0029595 |

3 X 0,34 |

4,8 |

10 |

40 |

|

| 0029596 |

4 X 0,34 |

5,2 |

15 |

48 |

|

| 0029599 |

12 X 0,34 |

9,4 |

40 |

130 |

|

| 0029600 |

18 X 0,34 |

11,2 |

60 |

170 |

|

| 0029601 |

25 X 0,34 |

13,1 |

83 |

220 |

|

| 0029608 |

18 G 0,5 |

12,3 |

84 |

202 |

|

| 0029609 |

25 G 0,5 |

15,2 |

120 |

284 |

|

| 0029610 |

2 X 1,0 |

6,3 |

19 |

60 |

|

| 0029611 |

3 G 1,0 |

6,6 |

28 |

71 |

|

| 0029612 |

4 G 1,0 |

7,2 |

38 |

87 |

|

| 0029614 |

7 G 1,0 |

9,2 |

65 |

141 |

|

| 0029615 |

12 G 1,0 |

12,4 |

110 |

237 |

|

| 0029616 |

14 G 1,0 |

13,2 |

128 |

257 |

|

| 0029617 |

16 G 1,0 + (2 x 1,0) |

15,4 |

190 |

346 |

|

| 0029618 |

18 G 1,0 |

16,1 |

170 |

349 |

|

| 0029619 |

23 G 1 + (2 x 1,0) |

18 |

250 |

461 |

|

| 0029620 |

25 G 1,0 |

17,8 |

240 |

407 |

|

| 0029621 |

34 G 1,0 |

21,1 |

320 |

600 |

|

| 0029622 |

41 G 1,0 |

23,6 |

390 |

753 |

|

| 0029624 |

4 G 1,5 |

8,2 |

57 |

114 |

|

| 0029625 |

5 G 1,5 |

9,1 |

72 |

141 |

|

| 0029627 |

7 G 1,5 |

10,5 |

101 |

187 |

|

| 0029629 |

12 G 1,5 |

14,3 |

170 |

294 |

|

| 0029630 |

18 G 1,5 |

17,5 |

259 |

450 |

|

| 0029631 |

25 G 1,5 |

19,7 |

360 |

661 |

|

| 0029632 |

3 G 2,5 |

9,1 |

72 |

136 |

|

| 0029641 |

4 G 6 |

13,3 |

220 |

330 |

|