-

產品搜尋

ALPHA-FIT-321-1-2

商品編號: ALPHA-FIT-321-1-2

ALPHA-FIT-321-1/2 熱縮管 Shrink Ratio 3:1 Dual Wall Flexible PO Thk Wall -55 to 125

AMS DTL-23053/4 Class 3, CA Prop 65, CSA 198, RoHS, UL 224

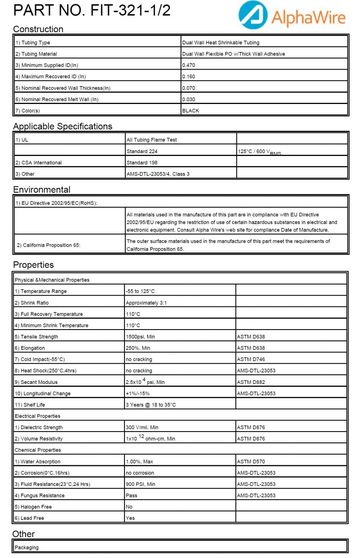

1) UL All Tubing Flame Test Standard 224 125°C / 600 VRMS 2) CSA International Standard 198 3) Other AMS-DTL-23053/4, Class 3 1) EU Directive 2002/95/EC(RoHS): All materials used in the manufacture of this part are in compliance with EU Directive 2002/95/EU regarding the restriction of use of certain hazardous substances in electrical and electronic equipment. Consult Alpha Wire's web site for compliance Date of Manufacture. 2) California Proposition 65: The outer surface materials used in the manufacture of this part meet the requirements of California Proposition 65. Physical & Mechanical Properties 1) Temperature Range -55 to 125°C 2) Shrink Ratio Approximately 3:1 3) Full Recovery Temperature 110°C 4) Minimum Shrink Temperature 110°C 5) Tensile Strength 1500psi, Min ASTM D638 6) Elongation 250%, Min ASTM D638 7) Cold Impact(-55°C) no cracking ASTM D746 8) Heat Shock(250°C,4hrs) no cracking AMS-DTL-23053 9) Secant Modulus 2.5x10 4 psi, Min ASTM D882 10) Longitudinal Change +1%/-15% AMS-DTL-23053 11) Shelf Life 3 Years @ 18 to 35°C Electrical Properties 1) Dielectric Strength 300 V/mil, Min ASTM D876 2) Volume Resistivity 1x10 12 ohm-cm, Min ASTM D876 Chemical Properties 1) Water Absorption 1.00%, Max ASTM D570 2) Corrosion(0°C,16hrs) no corrosion AMS-DTL-23053 3) Fluid Resistance(23°C,24 Hrs) 900 PSI, Min AMS-DTL-23053 4) Fungus Resistance Pass AMS-DTL-23053 5) Halogen Free No 6) Lead Free Yes Packaging 5X4 FT, 14X6 IN

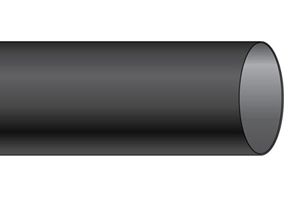

Part # Shrink Ratio Material Min Supplied ID Max Recovered ID Nom Recovered Wall Temperature FIT-295-3/64 2:1 SR XLPO 0.046 0.023 0.02 -55 to 135 FIT-295-3/8 2:1 SR XLPO 0.375 0.187 0.03 -55 to 135 FIT-300-1/2 3:1 SR XLPO 0.5 0.195 0.055 -55 to 125 FIT-300-1/4 3:1 SR XLPO 0.25 0.08 0.047 -55 to 125 FIT-300-1/8 3:1 SR XLPO 0.125 0.023 0.038 -55 to 125 FIT-300-3/10 3:1 SR XLPO 0.3 0.05 0.11 -55 to 125 FIT-300-3/16 3:1 SR XLPO 0.187 0.06 0.043 -55 to 125 FIT-300-3/4 3:1 SR XLPO 0.75 0.313 0.065 -55 to 125 FIT-300-3/8 3:1 SR XLPO 0.375 0.135 0.05 -55 to 125 FIT-321-1 3:1 Dual Wall Flexible PO Thk Wall 0.94 0.32 0.1 -55 to 125 FIT-321-1/2 3:1 Dual Wall Flexible PO Thk Wall 0.47 0.16 0.07 -55 to 125 FIT-321-1/4 3:1 Dual Wall Flexible PO Thk Wall 0.24 0.81 0.04 -55 to 125 FIT-321-1/8 3:1 Dual Wall Flexible PO Thk Wall 0.12 0.4 0.04 -55 to 125 FIT-321-1-1/2 3:1 Dual Wall Flexible PO Thk Wall 1.57 0.51 0.1 -55 to 125 FIT321MS1 FIT-321V-1/2 3:1 Flexible XLPO 0.472 0.16 0.033 -55 to 125 FIT-321V-1/4 3:1 Flexible XLPO 0.24 0.08 0.028 -55 to 125 FIT-321V-1/8 3:1 Flexible XLPO 0.12 0.04 0.024 -55 to 125 FIT-321V-1IN 3:1 Flexible XLPO 0.945 0.315 0.048 -55 to 125 FIT-321V-3/32 3:1 Flexible XLPO 0.06 0.02 0.02 -55 to 125 AMS DTL-23053/6 CL1 Colors, AMS DTL-23053/6 CL2 Clear, CA Prop 65, CSA 198, RoHS, UL 224, UL VW-1

★★★★商品規格描述★★★★ ALPHA FIT heat-shrink tubing offers a reliable way to protect and seal terminations or add additional mechanical ruggedness. FIT preferred heatshrink products are made from premium compounds under the tightest manufacturing controls. This means FIT will consistently have excellent physical characteristics such as low longitudinal shrinkage and wide temperature ranges while providing an elegant appearance when used alone or on OEM equipment.

ALPHA的 FIT 热缩管为保护和密封终端或提供额外的机械强度提供一种可靠的方式。FIT热缩产品是在严格的控制下利用高质量复合材料制造而成的。这意味着,FIT 将始终保持优良的物理特性,例如较小的纵向收缩率和较宽的温度范围,并且在单独使用或结合其它设备使用时,具有优雅的外观。

2024/4/29 下午 01:55:38

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司