-

產品搜尋

首頁 > ALPHA- 電線電纜專區> ALPHA-電線電纜專區 > ALPHA-Industrial Cable Applications 優質工業自動化應用電纜

ALPHA-INDUSTRIAL-VFD

Points to Consider When Specifying

High-Performance Cables

Shielding: Shielding provides signal protection

against radiated electrical noise. Flexible cables

require specific flex shielding to accommodate the

stresses of motion. Alpha Wire’s SupraShield® uses

both foil and braid shields to provide exceptional

shielding at both low and high frequencies.

Flexible vs. Flexing: Flexible refers to the ability of

cable to be bent to make installation and routing easier.

Flexing refers to the ability of a cable to withstand

movement allowing cables to be used in motion control

applications requiring millions of flex cycles.

Chemicals, Oils, Solvents, and Fuels: Cables must

be evaluated for their ability to tolerate exposure

to contaminants, including their severity and the

likelihood of exposure. Such resistance is primarily a

function of insulation and jacketing materials.

Temperature: Engineers will plan for the electronic/

electrical characteristics needed in extreme

temperatures, but may forget to “hazard-match”

their choice of cable to accommodate the additional

physical demands.

What is a VFD Cable?

Variable-frequency drives (VFD) allow sophisticated

control by AC motors by allowing their speed and

torque to be precisely adjusted. Drives use pulsewidth

modulation (PWM) to achieve same power

profile as a sine-wave frequency.

How Can PWM Affect the VFD Cable?

Several phenomena can affect power, create noise,

reduce life of the cable, and disrupt operation of the

drive system.

Standing Waves: Impedance mismatches in the

signal path causes signal energy to reflect backwards.

Reflected waves can re-reflect, cause the noise

to “stand” on the line. The impedance difference

between motors/drives and cables can be significant,

with the resulting increase in voltage degrading the

cable’s insulation and leading to eventual failure.

Corona Discharge: Discharges harm the cable by

degrading the insulation material and damaging

the cable’s shield. A corona discharge can generate

enough heat to melt the conductor’s insulation.

Thermosetting insulations such as cross-linked

polyethylene provide much better resistance to

corona discharges than PVC. Harmonic Distortion: All signals contain energy at

multiples of its frequency, in additions to energy at

its operating frequency. These signals result in wave

distortion due to a generation of harmonic energy.

In-Rush Current: When the motor is first started it

can draw very high current levels. Large VFD systems

can actually affect the power grid when they turn on.

EMI: Cables can emit or receive electromagnetic

energy as noise. This unwanted transfer of energy

to other circuits causes signal degradation, false

triggering, and other problems.Points to Consider When Picking a

VFD Cable

Insulation: The cable must have excellent dielectric

properties to prevent breakdown from stresses of

voltage and current spike, corona discharges, and

so forth. The properties of cross-linked polyethylene

(XLPE) makes it a better choice than standard

polyethylene or PVC.

Shielding: Serves the double purpose of keeping

noise generated by the VFD cable from escaping,

and preventing noise generated outside the system

from being picked up.

Cable Geometry: A round symmetrical cable gives

the best electrical performance and resistance to

deleterious effects.Flexing Cables

In selecting a cable for motion control, consider

not only the number of flex cycles but the type of

flexing. Cables are designed to withstand specific

types of flexing.

Rolling Flex: A continual back and forth

movement such as found in C-track or single-axis

Cartesian motion

Bending Flex or “tic-toc”: A back and forth

movement similar to a clock pendulum

Torsional Flex: A multiaxis movement that can

include twisting. A multiaxis articulated robot is

an example

Variable/Random Motion Flex: Irregular movement

with no defined regular path

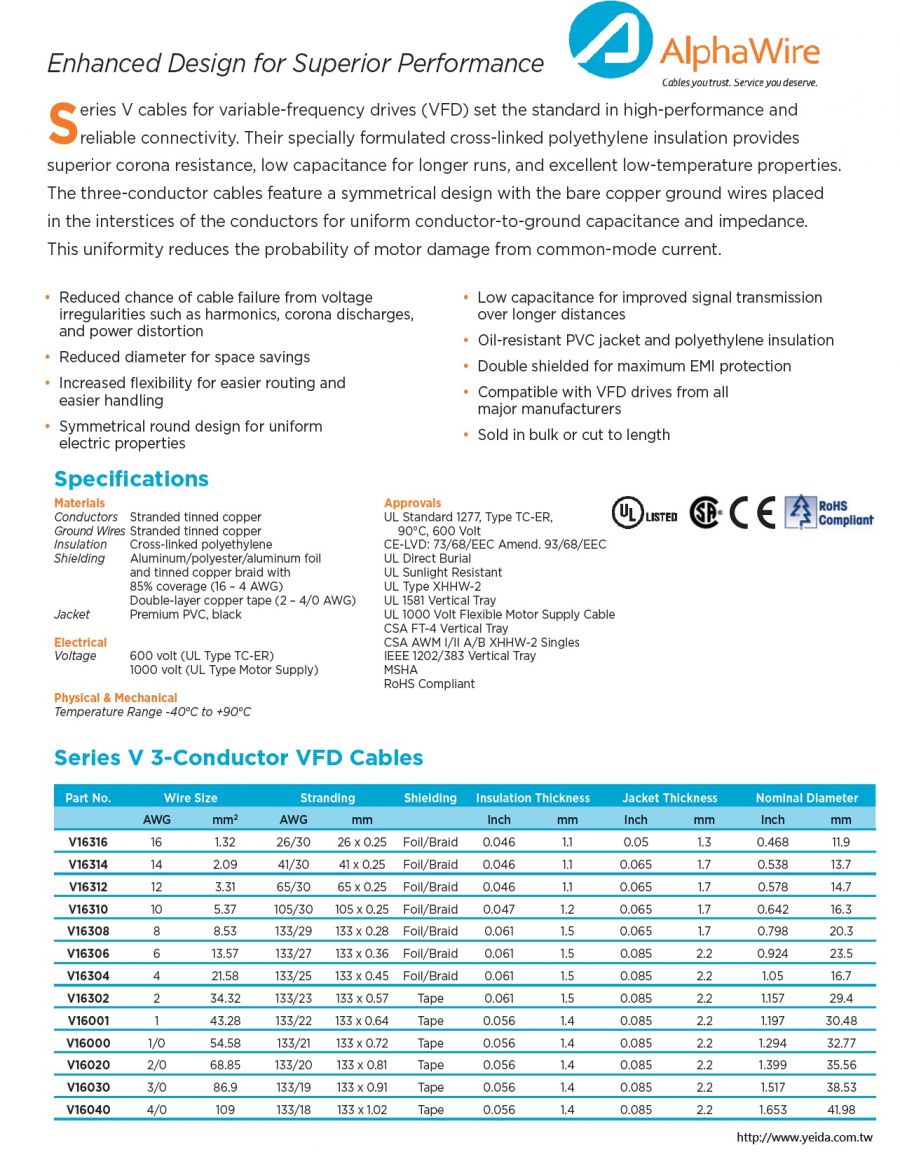

ForPart # Type Shielding Voltage AWG # of Conductors # of Elements Jacket Diameter V16000 Conductor Double Foil 600 1/0 3 3 1.294 CA Prop 65, CE, CSA AWM I/II A/B, CSA FT4, Pennsylvania Bureau of Mine Safety Approved, UL DIRECT BURIAL, UL EXPOSED RUN, UL SUN RES, UL TC, UL XHHW-2Wet/Dry V16001 Conductor Double Foil 600 1 3 3 1.197 V16002 Conductor FOIL/BRAID 600 2 4 4 1.308 V16004 Conductor FOIL/BRAID 600 4 4 4 1.157 V16006 Conductor FOIL/BRAID 600 6 4 4 1.017 V16008 Conductor FOIL/BRAID 600 8 4 4 0.92 V16010 Conductor FOIL/BRAID 600 10 4 4 0.746 V16012 Conductor FOIL/BRAID 600 12 4 4 0.633 V16014 Conductor FOIL/BRAID 600 14 4 4 0.584 V16016 Conductor FOIL/BRAID 600 16 4 4 0.547 V16020 Conductor Double Foil 600 2/0 3 3 1.399 V16030 Conductor Double Foil 600 3/0 3 3 1.517 V16040 Conductor Double Foil 600 4/0 3 3 1.653 V16108 Composite FOIL/BRAID 600 8+14 4 + 1 Pair 5 1.032 V16110 Composite FOIL/BRAID 600 10+14 4 + 1 Pair 5 0.875 V16112 Composite FOIL/BRAID 600 12+14 4 + 1 Pair 5 0.785 V16114 Composite FOIL/BRAID 600 14+14 4 + 1 Pair 5 0.743 V16116 Composite FOIL/BRAID 600 16+14 4 + 1 Pair 5 0.717 V16302 Conductor Double Foil 600 2 3 3 1.157 V16304 Conductor FOIL/BRAID 600 4 3 3 1.05 V16306 Conductor FOIL/BRAID 600 6 3 3 0.924 V16308 Conductor FOIL/BRAID 600 8 3 3 0.798 V16310 Conductor FOIL/BRAID 600 10 3 3 0.642 V16312 Conductor FOIL/BRAID 600 12 3 3 0.578 V16314 Conductor FOIL/BRAID 600 14 3 3 0.538 V16316 Conductor FOIL/BRAID 600 16 3 3 0.468

2025/7/13 下午 03:43:16

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司