-

產品搜尋

首頁 > ALPHA- 電線電纜專區> ALPHA-FIT® Heat-Shrink Tubing 熱縮管 > ALPHA-FIT 2:1 Shrink Ratio Heat-Shrink Tubing 通用熱縮管

ALPHA-FIT-CLEAR-1-2

商品編號: ALPHA-FIT-CLEAR-1-2

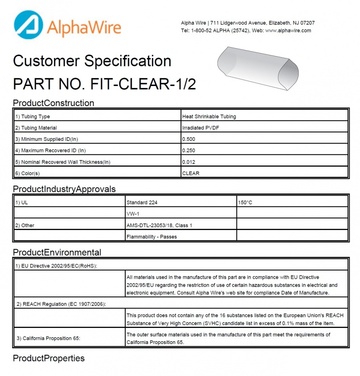

ALPHA-FIT-CLEAR-1/2 2:1 IRR PDVF Kynar -55 to 175 °C CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 氯化聚烯烃熱縮管

Cross-linked PVDF Transparent after shrink Fast recovery time Excellent chemical, heat, and flame resistance Passes UL VW-1 flame test 2x the tensile strength of standard polyolefin

交联聚偏二氟乙烯 收缩后透明 快速的收缩时间 优异的耐腐、抗热和耐火性能

通过 UL VW-1 火焰试验 抗张强度是标准聚烯烃的 2倍Part # Shrink Ratio Material Min Supplied ID Max Recovered ID Nom Recovered Wall Temperature Ratings FIT-CLEAR-1/2 2:1 IRR PDVF Kynar 0.5 0.25 0.012 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 Part # Shrink Ratio Material Min Supplied ID Max Recovered ID Nom Recovered Wall Temperature Ratings FIT-221-MS-1 2:1 XLPO -55 to 135 AMS DTL-23053/5 CL 1 Colors, AMS DTL-23053/5 CL 2 Clear, CA Prop 65, CSA 198 Except Clear, RoHS, UL 224 Except Clear FIT-221-MS-2 2:1 XLPO -55 to 135 AMS DTL-23053/5 CL 1 Colors, AMS DTL-23053/5 CL 2 Clear, CA Prop 65, CSA 198 Except Clear, RoHS, UL 224 Except Clear FIT-321-MS-1 3:1 Dual Wall IRR PO -55 to 110 AMS DTL-23053/4 Class 3, CA Prop 65, CSA 198, RoHS, UL 224, UL VW-1 FIT-CLEAR-1/16 2:1 IRR PDVF Kynar 0.063 0.031 0.01 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-1/2 2:1 IRR PDVF Kynar 0.5 0.25 0.012 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-1/4 2:1 IRR PDVF Kynar 0.25 0.125 0.012 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-1/8 2:1 IRR PDVF Kynar 0.125 0.062 0.01 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-1-1/2 2:1 IRR PDVF Kynar 1.5 0.75 0.02 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-1IN 2:1 IRR PDVF Kynar 1 0.5 0.019 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-2IN 2:1 IRR PDVF Kynar 2 1 0.02 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-3/16 2:1 IRR PDVF Kynar 0.187 0.093 0.01 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-3/32 2:1 IRR PDVF Kynar 0.093 0.046 0.01 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-3/4 2:1 IRR PDVF Kynar 0.75 0.375 0.017 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CLEAR-3/64 2:1 IRR PDVF Kynar 0.046 0.023 -55 to 175 AMS DTL-23053/18 Class 1, CA Prop 65, RoHS, UL 224, UL VW-1 FIT-CLEAR-3/8 2:1 IRR PDVF Kynar 0.375 0.187 0.012 -55 to 175 AMS DTL-23053/18, CA Prop 65, Class 1, RoHS, UL 224, UL VW-1 FIT-CRIMP-1 2:1 Nylon 0.17 0.055 -55 to 125 MIL-T-10727 Type 1, UL FIT-CRIMP-2 2:1 Nylon 0.197 0.08 -55 to 125 MIL-T-10727 Type 1, UL FIT-CRIMP-3 2:1 Nylon 0.255 0.11 -55 to 125 MIL-T-10727 Type 1, UL

2024/5/19 上午 05:14:23

- YEIDA宜大電線有限公司

- 宜大(YEIDA) 為美國 BELDEN and ALPHA 公司 代理商 (經銷商)

- E-mail: yeida.lin@msa.hinet.net

- E-mail : yeida@ms79.hinet.net

- TEL:(02)2995-4668(代表號) FAX:(02)2278-1798

- 地址:新北市三重區重新路五段639之1號9F

網站所採用資料及圖檔皆屬各公司所有, 本公司決無侵權之意,如有造成不便,請聯絡本公司